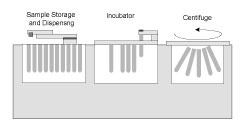

This use case looks at how you can create coordinated, multi-motor, multi-axis motion for a compact tabletop clinical device such as a blood analyzer.

Application Challenge

Efficiently and cost-effectively create a motion control architecture that can support multiple axes and multiple motor types while maintaining the compact table‐top size of the equipment.

Application Considerations

| Feature/Function | Units |

| Control architecture: | Board‐based |

| Number of axes: | 7 - 10 |

| Motion mode: | Point‐to‐point, multi‐axis point‐topoint, velocity control |

Motion Control Solution

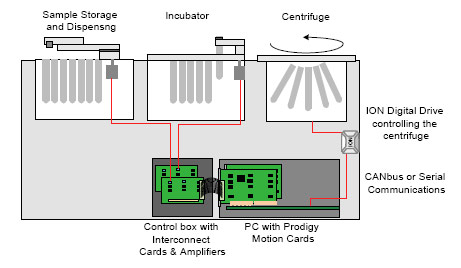

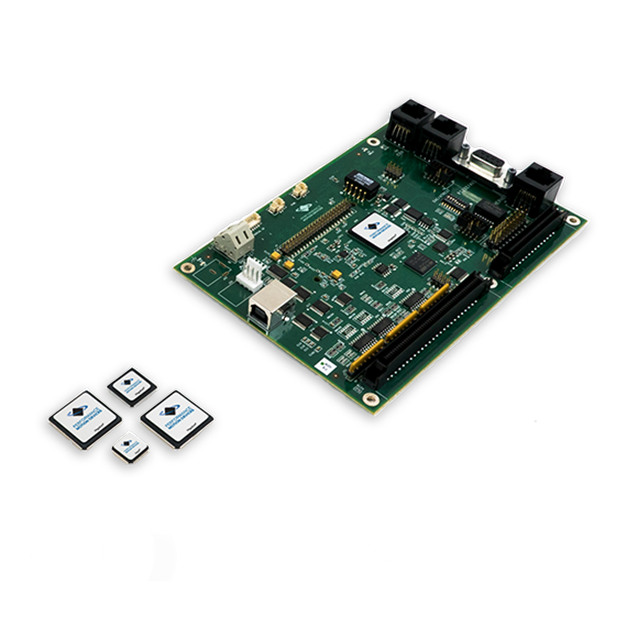

This application is well suited for 2‐3 Prodigy® PCI Motion Boards and an ION® 500 Digital Drive. The ION Drive is used for spinning the centrifuge and the Prodigy Motion Boards for the 2‐ to 3‐axis arms and 1 rotor each, in the sample storage carousel, and incubator. This motion control architecture could be designed in several alternate ways depending on the machine’s requirements. A PCI, PC/104 or stand‐alone format could be chosen for the motion cards with each having advantages. If compact size is a consideration then the PC/104 format could reduce the overall control system size by using stacked motion cards mounted on the control system mother board. If a more distributed architecture is needed then the stand‐alone format can be used to mount the motion cards at the subsystems.

Velocity Profile Mode with Time Break Points

Using the velocity profile mode the centrifuge can be set up to run at various the velocities at predetermined time points that match the specific process to achieve variable speed control and the resulting R.C.F. (relative centrifugal force). In this mode, the motion is controlled by changing the acceleration, velocity, and deceleration parameters while the profile is being executed. The ION Digital Drive supports up to 2 breakpoints. The trigger condition can be one of 10 parameters. For this application the trigger condition is Time. At each trigger point, the acceleration and velocity parameters are updated and the next set of parameters loaded.

Motion Control Programming

Programming the Prodigy Motion Boards and the ION Digital Drive is managed with C‐Motion®, a source code library of motion commands for development of C/C++ programs that run on the on‐board host.

Learn more about our Developer Kits and Developer Software which makes getting your machine to market much faster.

Multi-motor Support

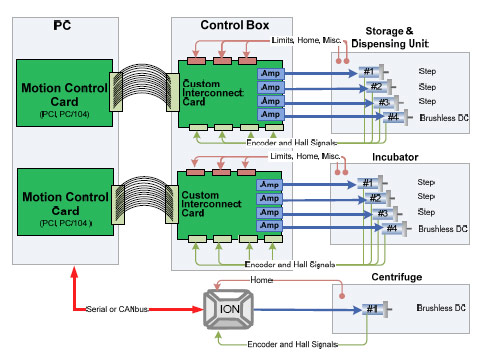

Prodigy Motion Boards support multiple motor types, including DC Brush, Brushless DC, and Stepper, and also pulse and direction amplifiers. Each axis on a card can be a different motor type. This allows for optimized motor selection in the system for both cost and performance. For example, in Figure 1 the 2‐ to 3‐axis arm in the sample storage carousel and the incubator use step motors and the incubator and storage carousel rotors are Brushless DC motors.

Figure 1: Connections from PCI to Prodigy boards and ION drives

Figure 1 illustrates the connections from the PC to the Prodigy PCI motion boards and ION Digital Drive, interconnect cards, amplifiers, and motor for the centrifuge unit. Figure 2 shows the overall system controlling 7 to 10 axes.

Figure 2: Blood Analyzer application controlling 7 to 10 axes

All Prodigy Motion Boards and ION Digital Drives provide high-performance, reliable motion control support for multiple motor types including DC Brush, Brushless DC, Step, and Microstepping motors, and are based on our Magellan® Motion Processor, which provides user‐selectable profile modes including S‐curve, trapezoidal, velocity contouring, and electronic gearing.

All Prodigy Motion Boards and ION Digital Drives provide high-performance, reliable motion control support for multiple motor types including DC Brush, Brushless DC, Step, and Microstepping motors, and are based on our Magellan® Motion Processor, which provides user‐selectable profile modes including S‐curve, trapezoidal, velocity contouring, and electronic gearing.

Please do not hesitate to contact us at +1 978.266.1210 for more information, including details on Developer& Kits which help you start fast and work quickly. We are always available to assist you in improving your motion control systems.

You may also be interested in:

- Optimize Control of Syringe Dispensing Application

- Field Oriented Control (FOC) - A Deep Dive

- Motoring to Success

- Servo Tuning Deep Dive: Black art, rocket science, or walk in the park?

Stay ahead of the competition.

If your existing equipment needs a performance boost or if you need to develop a new product in the shortest development time possible, learn about motion control solutions from Performance Motion Devices.

- 2X faster development

- Motion solutions from ICs to turn-key boards

- Easy to implement

- Always supported