What’s A Motion Control Amplifier?

A motion control amplifier is basically the electronics used to drive positioning and velocity controlled motors such as step motors, DC Brush motors, Brushless DC motors, and AC motors.

What Is The Difference Between A Motion Amplifier and A Motion Controller?

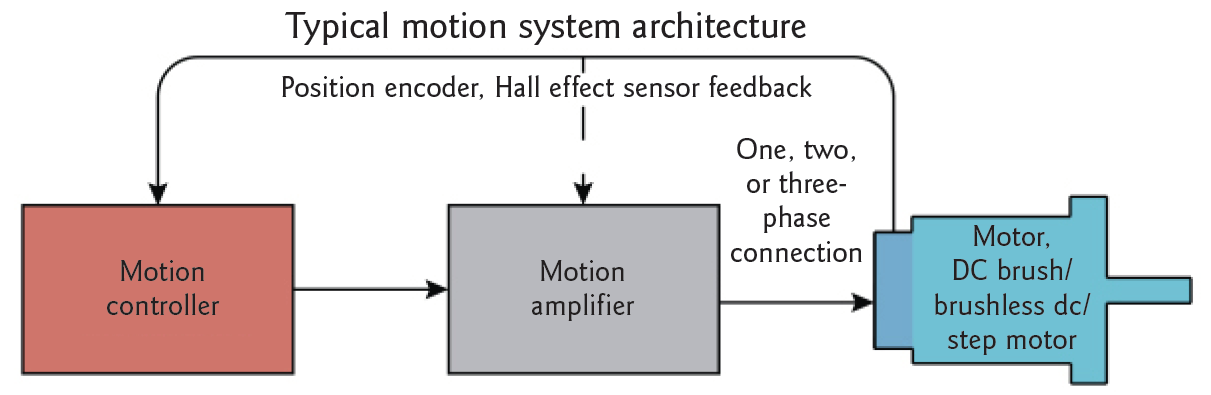

A motion controller generates set points necessary to realize the desired output or motion profile. It also closes a position or velocity feedback loop to calculate the amount of error between the commanded position and the actual position of the system. The motion controller closes the loop through use of feedback from one or more sensors such as optical encoders, resolvers or Hall effect devices which monitor the position or velocity of the actuator. The motion controller generates a command signal based on the amount of this instantaneous error.

In contrast, a motion amplifier transforms the control signal from the motion controller into a sufficiently high-power electrical current or voltage that is what actually causes the actuator to move.

What Components Go Into A Motion System?

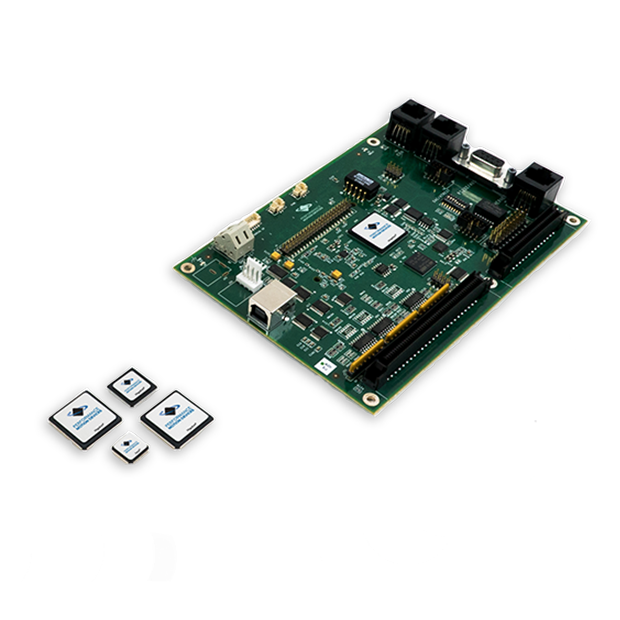

The two key components are the motion controller and the motion amplifier. The motion controller is often board or card-based. Controllers in this format are available off-the-shelf from a number of vendors. Alternatively, the controller could take the form of a module, probably boxed together with the amplifiers.

If the motion controller can be simply an integrated circuit (IC) mounted on a card, there are a few choices regarding the system configuration. You can install a general purpose microprocessor and program it with code to perform the motion control functions. These functions include profile generation, PID position loop control (for servo motors), and other timing and synchronization functions as needed for your application.

But it can be tricky to write all that code, so another popular choice is to buy a dedicated motion control IC. These ICs, or chips, connect to a general purpose microprocessor and provide a range of ‘canned’ motion functions. Installing an off-the-shelf motion processor IC shortens the project development time and generally gives the application access to more sophisticated motion features such as S-curve velocity profiling, advanced servo loop features such as bi-quad filtering, and auto-tuning.

Figure: Typical motion system architecture

Are Motion Control Amplifiers Analog Or Digital?

Controls today have gone digital. Inexpensive digital signal processors rather than discrete components typically generate motor coil waveforms. Use of DSPs makes possible more sophisticated control techniques that bring higher efficiency and precision.

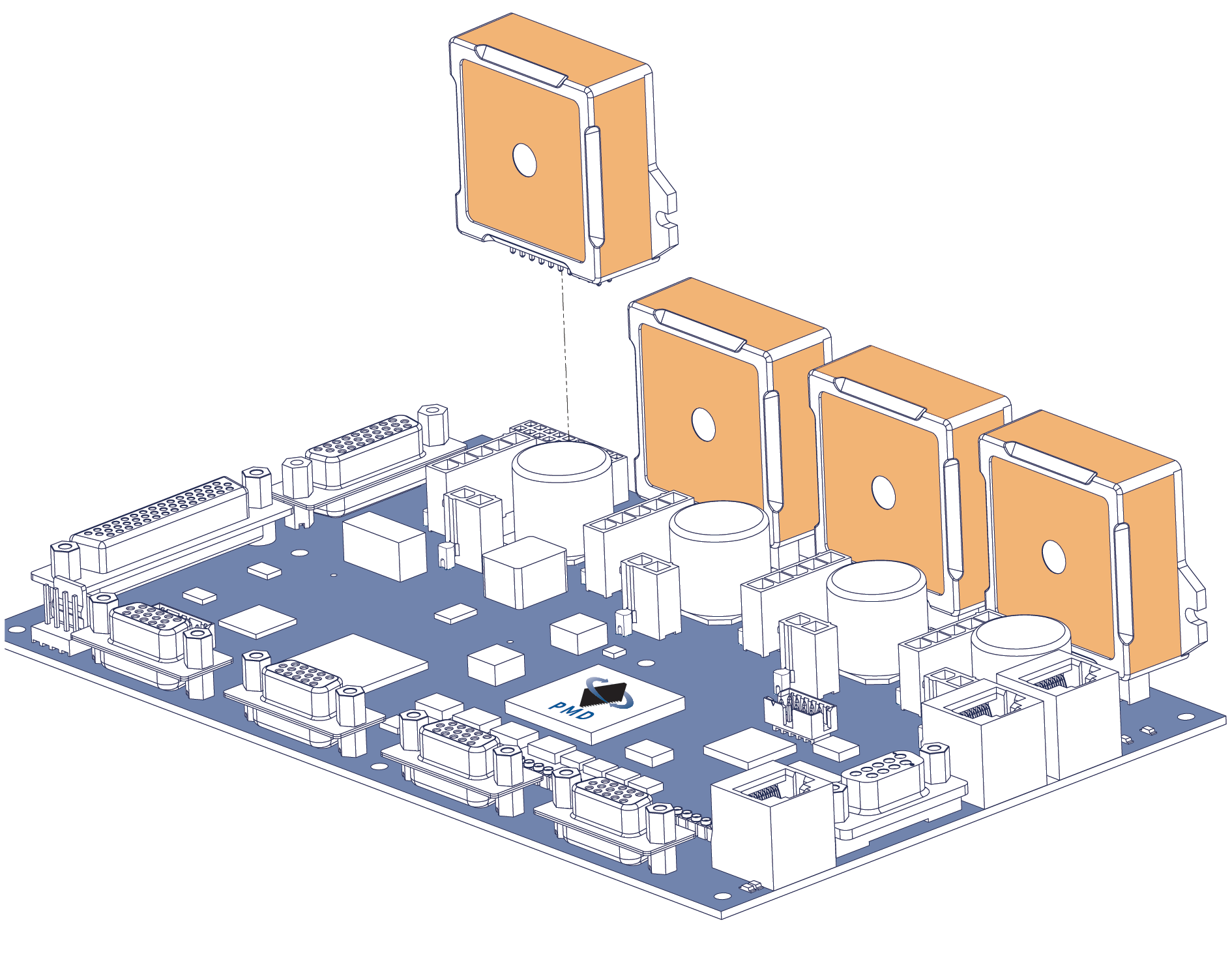

How Big Is A Motion Control Amplifier?

MOSFETs and IGBT switching transistors become more efficient all the time. The trend now makes it possible to locate all control electronics on a single card, or in a single box. Consequently, modern motion control amplifiers have a smaller number of cables, are easier to service, and are more reliable than older technology.

What Does A Digital Motion Amplifier Do?

At the core, motion amplifiers accept a control signal, either analog (nearly always ± 10 V) or in digital form (either Serial Peripheral Interface or Pulse Width Modulation, serial RS232, or a network protocol such as CANbus). The control signals govern the degree and timing of amplification by controlling high-efficiency bridges that rapidly switch between supply voltage and ground. The amplifier actively controls the current through each motor coil.

The process of controlling motor coil current is tricky both because each coil is an inductor and because the motor generates ‘back EMF’ as it rotates. Back EMF degrades performance unless the amplifier corrects for it. Finally, for step motors and brushless dc or ac motors, the ampli- fier provides phasing. This means the amplifier continually adjusts the commanded current through each motor coil as the motor rotates.

How Do You Spec A Motion Amplifier?

The first big consideration is power level. At lower voltages and currents - roughly 10 to 60 V and 4 A or less - inexpensive IC-based motor amplifiers might suffice. They don’t always provide the most advanced motor control techniques, but they get the job done in a wide variety of applications. Solderable amplifier modules are the next step up in capability. They provide up to a kilowatt of output yet are still compact, occupying a volume of about one cubic inch. These are true dedicated motor amplifiers and provide sophisticated current control and phasing through use of advanced algorithms that the DSP executes. Finally, module-based amplifiers become candidates as voltages and currents exceed 60 V and 10 A. These cable-connected devices provide all the functions of the solderable modules, but can mount away from the control card for better heat dissipation and EMI isolation.

What Is The Advantage Of Using A Digital Motion Amplifier Rather Than An Analog Version?

There are several advanced motor control techniques that require the ability to perform math calculations. Math is relatively easy to do with a DSP, or DSP-like circuit but difficult to do with discrete components. A notable example is field-oriented control, a technique which uses mathematical algorithms to optimize the generation of phase waveforms for Brushless DC and AC induction motors, while giving higher peak rotation speed and efficiency.

Another area where digital control is helpful is in managing and optimizing the control parameters. An example would be PID loop parameters for velocity or current control. Older amplifiers set these gains manually via screw adjustments, whereas digital amplifiers simply store parameters electronically in non volatile memory.

You may also be interested in:

- Keep Your Step Motor Position with A Closed Loop Motion Control System

- Digital Current Loop Significantly Quiets Step Motor Noise

- Optimizing A Control Architecture for High Accuracy Syringe Dispensing

- Field Oriented Control (FOC) - A Deep Dive

Don't let motion control slow you down.

Rely on the experts at PMD Corp. to keep your project moving. If your existing equipment needs a performance boost or if you need to develop a new product in the shortest development time possible, learn about motion control solutions from Performance Motion Devices.