Synchronizing motion with CAM profiles

Product labeling machines come in many shapes and sizes. Often, the product to be labeled is riding on a conveyor belt and the product labeler is on a moving stage that must stay synchronized to the conveyor belt. How do we build a general purpose labeler carriage that always precisely aligns to the moving product, but can still be used with a variety of conveyor systems, product shapes, and assembly line mechanisms? This use case explores the process, considerations and motion contro solutions that will help you design and build an automatic product labeler machine.

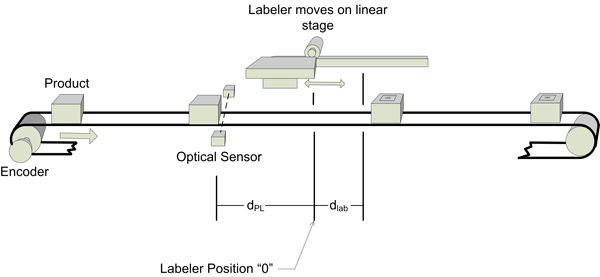

Figure 1: Product Labeling Process

Application Considerations

|

Feature / Function |

Unit / Description |

|

|

Motion Mode |

CAM profiling, labeler will serve as a slave to conveyor belt motion |

|

|

Control Architecture |

Board-based (should accept embedded user code to mitigate communication latencies) |

|

|

Feedback Devices |

Optical switch to determine position of product and encoder on conveyor belt |

Motion Control Solution

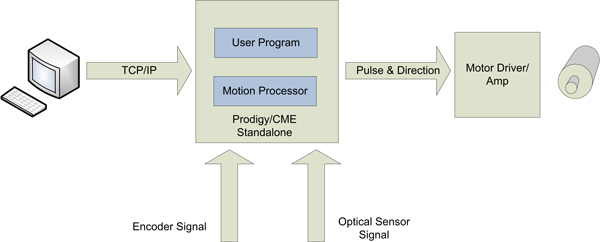

The motion solution recommended for this application is a Prodigy®/CME Machine-Controller board used to control the labeler motion stage (See Figure 2). A successful label application requires that the motion of the labeler track the motion of the conveyor belt. This is accomplished by placing an encoder on the conveyor belt, which serves as a master signal to control the labeler’s motion.

Figure 2: Labeler controller system

The heart of the labeler control approach is a programmable CAM profile. By programming a setup-specific CAM profile, a wide variety of conveyor and labeler geometries can be compensated for, while still holding the labeler precisely over the moving product.

An optical sensor is located at a known distance from the home position of the labeler. When the product breaks the optical beam, a high speed position capture is triggered on the labeler controller allowing, it to know the positional relationship (encoder counts) between the product and labeler. This relationship continues to be tracked until the labeling procedure has completed.

The information is used to kick-start the labeler’s motion when the encoder reaches a specific value. The result of the kick-start is that the labeler will follow the product very precisely. The labeler axis will undergo an acceleration move as specified by the CAM, apply the label, and then decelerate and recirculate its position to the initial start position.

The Prodigy/CME (C-Motion Engine) Machine-Controller forms a complete all-in-one control solution, requiring only a power supply, motors, and cables to be fully functional. Performance Motion Devices Atlas® Digital Amplifiers are directly located on the Machine-Controller and provide sophisticated current control of all the system motors, safety checking, and total drive capacity up to 1 Kilowatt per axis.

Going Further

The use of a CAM profile as the general purpose path specification allows the labeler motion carriage to accommodate a large variety of assembly line geometries. One major variation is that the labeler is not mounted on a linear stage, but rotates in a circle. In this scenario instead of moving backwards to recirculate the labeler to the starting position, the axis continues to rotate forward to the recycle/start position, whereupon it stops and waits for the optical sensor to indicate the next 'start' motion.

Pro-Motion® Development Software allows the entire configuration setup to be saved to a named file so that various motors, as well as various servo control schemes, can be explored.

Prodigy®/CME Machine-Controller& boards integrate high-performance amplifiers with a full motion control package. Featuring up to four on-card ATLAS® Digital Amplifiers, Machine-Controller eliminates the need for external amplifiers, allowing new levels of convenience, integration, and cost savings for applications in life sciences equipment, scientific automation, robotics, and general purpose automation.

Prodigy®/CME Machine-Controller& boards integrate high-performance amplifiers with a full motion control package. Featuring up to four on-card ATLAS® Digital Amplifiers, Machine-Controller eliminates the need for external amplifiers, allowing new levels of convenience, integration, and cost savings for applications in life sciences equipment, scientific automation, robotics, and general purpose automation.

Contact our customer support team (or +1-978-266-1210) for more information including details on Developer’s Kits and application support. We welcome the opportunity of assisting you in improving your motion control system.

Learn more about our motor control boards or order your Prodigy/CME Machine-Controller Develop Kit online.

You might also be interested in:

- Packaging Automation - A Deep Dive

- Keep Your Step Motor Position with A Closed Loop Motion Control System

- Field Oriented Control Deep Dive

- Our full line of Motion control ICs