Low weight and precise torque control are the key to controlling very high-performance, general purpose end effectors.

Application Challenge

End effectors used in lab automation, robotics, packaging, and materials handling applications take on many forms and have a wide range of torque and speed requirements. What they share in common is a requirement for excellent torque control, low cost, and versatility. But, how do we build those features into a general purpose controller that works with a wide range of mechanical effectors, performs torque as well as position control, weighs less than 1.75 oz, and drives milliamp loads all the way up to 12 amp loads?

Application Considerations

|

Feature/Function |

Unit/Description |

|---|---|

|

Control card target weight |

1.65 oz |

|

Input voltage range |

12 to 48 volts |

|

Current range |

0 to 11.5 amps |

|

Torque control resolution |

.05% or better |

|

Actuator types |

Voice coil, DC Brush, Brushless DC motor |

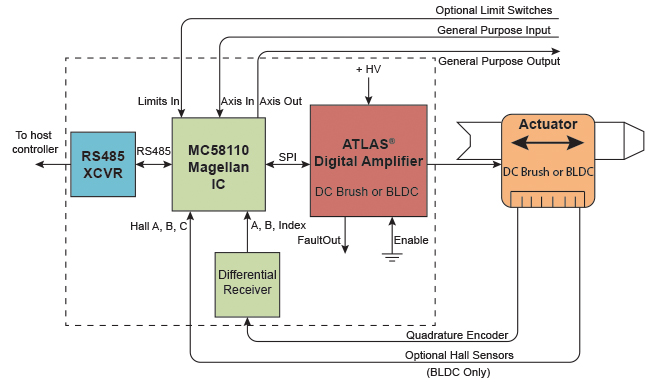

Figure 1: System Diagram

Figure 1: System Diagram

Motion Control Solution

In this application a single axis Magellan® Positioning IC is coupled with an Atlas® Digital Amplifier to provide very high performance torque control and position control of the load. As the system diagram above shows, the actuator, which can be either a voice coil, a DC Brush motor, or a 3-phase Brushless DC motor, is directly driven by the Atlas amplifier.

Atlas accepts continuous torque commands from the Magellan IC, which inputs quadrature encoder signals in positioning applications and limit switches for certain actuator types. The Magellan IC provides several profiling modes including trapezoidal, s-curve, or electronic gearing to smoothly ramp the torque or position command sent to the Atlas amplifier.

The Magellan connects to the Atlas Amplifier via an SPI (Serial Peripheral Interface), and provides an RS485 interface to the off-card system controller. The Magellan also provides a general purpose input and output for end effectors that require these additional control I/Os.When used with an effector that uses a BLDC motor, the Magellan IC inputs Hall sensors and optionally quadrature encoders to commutate the motor.

A single motor supply voltage is provided to Atlas, which provides extensive torque control and safety checks including over current detect, bus voltage over and under voltage, over temperature, and more. The basic current resolution of the Atlas is .024%, easily meeting the current control specification.

Performance Motion Devices' Pro-Motion® software allows the Magellan and Atlas to be tuned and optimized for any given actuator and application. High speed variable trace allows even the most rapid moves to be analyzed and manually optimized. Alternatively, an Axis Wizard and auto-tuning feature lets users set up and get running quickly.

Going Further

Both Magellan and Atlas units can be purchased for step motor control with no software changes or other package reconfiguration of the controller. If the step motor version of Atlas is used, two phases are directly driven with bipolar control of each coil, and microstep positioning with up to 256 microsteps per full step is provided.

Depending on the nature of the step-motor-based end effector, Atlas's separate holding/drive currents can be programmed for minimum heat generation in the motor. In step motor mode the Magellan IC can still accept quadrature encoder feedback, which may be used to verify position in applications where 100% position confirmation is required.

ATLAS® Digital Amplifiers

ATLAS® Digital Amplifiers

ATLAS® Digital Amplifiers are compact single-axis amplifiers that provide high performance torque control of DC brush, Brushless DC, and step motors. They are packaged in a compact solderable module and utilize standard through-hole pins for all connections.

You may also be interested in:

- Digital Current Loop Significantly Quiets Step Motor Noise

- Improving Liquid Handling Robot Throughput by means of Direct Path Planning and Obstacle Avoidance Programming

- Optimizing A Control Architecture for High Accuracy Syringe Dispensing

- Keep Your Step Motor Position with A Closed Loop Motion Control System

Stay ahead of the competition.

If your existing equipment needs a performance boost or if you need to develop a new product in the shortest development time possible, learn about motion control solutions from Performance Motion Devices.

- 2X faster development

- Motion solutions from ICs to turn-key boards

- Easy to implement

- Always supported