When engineers think of advances in motion control technology, they usually think of faster motors, improved accuracy, or seemingly neverending improvements in MOSFET efficiency. While these advances are important, equally important are changes that have come in less publicized areas, particularly in the architecture of the motion controller.

This article will examine some of these trends, and detail the four major motion control architectures in use today, two of which can be traced back to earlier motion control approaches, and two of which are more recent additions.

The past is prologue

Up until about ten years ago, there were just two basic types of motion controllers. The first is shown in Figure 1, and is one form or another of a multi-axis motion card. In this architecture, the motion card connects to external amplifiers, which generally accept +/- 10V analog signal input, and control torque or sometimes velocity of the motor. Early on, the path planning and servo feedback required a dedicated numerical computer and was often rack mounted. Today, variations on this approach center around card bus type. Popular formats today include PCI, PC/104, compact PCI, and Ethernet.

This architecture has a number of important advantages, primary among them flexibility. The motion controller is independent of the motor power level, and often even the motor type. For example if the motion controller outputs a single phase +/- 10V signal, this can be connected to a DC Servo motor amplifier, or a Brushless DC motor amplifier which in turn performs commutation. If the user wants to increase the power of the motor, or change the motor type, the motion card doesn't need to be changed, only the amplifier.

Another important advantage of multi-axis motion cards is that synchronization among axes is straightforward, and essentially automatic. This is because most such systems generally use a single CPU (central processing unit) or DSP (digital signal processor) to “time-slice” its computation for each axis. Taking advantage of this capability, some motion cards provide builtin multi-dimensional profiling commands such as “draw an arc with radius x” or even support complete machine tool instruction sets such as G-code.

The primary disadvantage of this architecture is wiring complexity, and cost. For a typical servo motion axis, there are 15-25 wires that connect to and from each motor axis, depending on whether differential signals are used, and whether the controller or the amplifier performs commutation. Imagine building a controller for a ten-axis system using this approach. You would need bundles carrying hundreds of wires through the machine. This is a complex, costly, and potentially failure-prone design.

Little black boxes

The second approach, also still in use today, is the standalone motor drive, also known as a smart amplifier. In this approach the controller is a “box,” and is usually rack or rail mounted. The drive either plugs into the wall, or is fed with a DC bus voltage. This architecture is shown in Figure 2.

There are many variations of how such stand-alone drives are controlled. Most of them can be controlled by a PLC (programmable logic controller) using digital inputs, and pre-programmable locations. More modern variations include the ability to download programs into a on-board memory, so that each drive can execute an autonomous sequence of actions such as, “start the motor at speed x, when signal y goes high then coast to a stop....” In addition to variations in how they are programmed, standalone drives are also available in multi-axis configurations. Stand-alone drives such as this work well when the behavior of each axis is fairly simple, and more or less autonomous. Using this approach it would be difficult to synchronize two or three such drives to follow a precise multi-dimensional curve, but it is easy to repeat a basic motion, or track an incoming encoder signal and execute master/slave electronic gearing or an electronic camming.

Compared to motion cards, the advantage of standalone drives is that wiring is simplified. Since the connections between the calculation portion and the amplifier portion of the controller are internal to the drive, all of the wiring used to interconnect a motion card to an amplifier is eliminated. Another advantage is that drives can be located essentially anywhere in the machine, saving cost and improving reliability by shortening cable distances. The central disadvantage, at least historically, of stand-alone drives is that they tend to be big and expensive, particularly for multi-axis control. This is because using older technology, packaging a profile generator, an amplifier, and a AC to DC or DC to DC power converter meant it had to be big.

Out of the rack... and into the fire

The third motion architectural approach, known as a distributed drive, combines the synchronization ability of multi-axis motion cards with the reduced wiring and increased robustness of standalone drives. Such a drive uses a network connection to communicate with a central host, but still has all the standard drive features of profile generation, amplification, and internal AC or DC power management. This architecture is shown in Figure 3.

Depending on the application required, two kinds of distributed drives are used. The first can be referred to as a tightly coupled drive, and uses high speed, deterministic networks such as SERCOS, Firewire, EtherCat, or Ethernet/Powerlink.

The second can be referred to as a loosely coupled drive, and uses slower speed networks such as CANbus and RS-485, or less deterministic networks such as Ethernet.

One big difference between loosely coupled and tightly coupled distributed drives is that tightly coupled drives require a motion card to synchronize and coordinate the motion of each axis. Loosely coupled drives are controlled directly from the host, by sending commands such as “move the axis to position x using a point-to-point s-curve.” Tightly coupled drives are very different in that each drive receives rapid, synchronized, position and/ or velocity updates, generally several hundred, or even several thousand times per second.

The advantage of distributed drives is reduced wiring and increased reliability. Another big advantage is scalability. Adding one more axis to a distributed drive network is a simple matter of plugging in another drive. In multi-axis motion card architectures, adding another axis can require a whole new card purchase in the situation that (for example) a fifth axis must be added to a 4-axis card. Distributed networks also have the advantage that it is also much easier to mix and match motor types. For example a network could be constructed with some DC Servo motors, some Brushless DC motors, and some step motors. As long as each drive talks the same “language” on the network, the host software need not be aware of motor type.

Roll your own

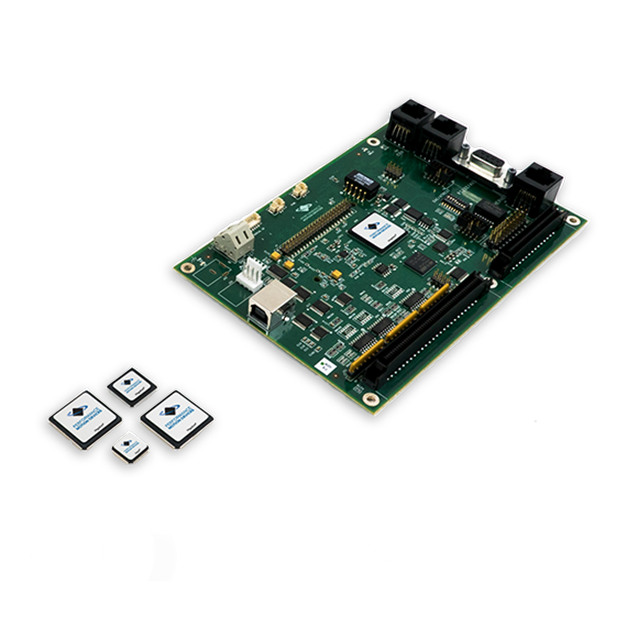

The fourth major type of motion controller in use today can be referred to as an integrated motion card. In this approach, shown in Figure 4, the advantages of reduced wiring are combined with easy multi-axis synchronization by locating the amplifiers on the multi-axis card itself.

The advantage of this approach is very low cost, since there are no drives or amplifiers to purchase. The main disadvantage is that the motor drive power levels tend to be low, because high switching voltages and heat are incompatible with sensitive digital logic circuitry.

It is worth noting that unlike multi-axis motion boards, which are available from a number of off-the-shelf product vendors, integrated cards are generally designed specifically for a given application. This can be done either by programming a CPU or DSP, or by using off-the-shelf motion processors. Motion processors are IC-based devices that greatly simplify the task of designing a motion card by providing built-in functions such as trajectory generation, servo loop closure, commutation, as well as other functions.

Let’s hit the road

When is one motion control architectural approach used over another? There is no easy, simple answer, and sometimes two architectures can be used with success for a given application.

In broad terms, the more cost sensitive the application, the more likely it is that you will design your own card, and if possible, integrate on-board amplifiers. Since you are designing your own card you can choose exactly the connectors you want, and dimension the form factor of the card for your own application. Highly synchronized applications such as machine tools will gravitate toward either a multi-axis motion card, or more likely a tightly-coupled distributed drive approach. While not cheap, these drives allow a lot of flexibility in motor type and power range. Don’t forget that you will still need a motion control card for overall path generation, and to correctly split up and send out the motion segments to each individual drive axis. Be aware that in theory the card and the drive could be from separate vendors, but in practice this is seldom the case.

The larger middle ground of applications such as medical automation, semiconductor automation, scientific instrumentation, and low-power general automation, is generally served by loosely- coupled distributed drives, or by multi-axis motion cards. Factors that tilt the solution toward distributed drives include larger number of axes, and use of two or more different motor types. Factors which tilt the solution toward multi-axis cards are the need for synchronization, smaller number of axes, or use of a single motor type.

Another factor in determining the importance of adopting drives versus a multi-axis motion card architecture is the physical size of the machine. Generally speaking, the larger the system, the greater the reliability improvement in locating the drive close to the motor. But if the whole machine is already fairly small, locating the drive close to the motor will not be a big factor in the decision.

Summary

In the past ten years, new motion control architectures have been developed which offer reduced wiring and improved reliability. Choosing the right architecture is a matter of understanding the requirements of your application. Many factors will impact the final decision in choosing the correct architecture, including whether the axes are tightly synchronized or not, the total number of axes in the application, the desired system cost, the size of the machine, and whether more than one motor type will be used.

Article written by:

Chuck Lewin

Founder & CEO

Performance Motion Devices, Inc.

Stay ahead of the competition.

If your existing equipment needs a performance boost or if you need to develop a new product in the shortest development time possible, learn about motion control solutions from Performance Motion Devices.

Related topics:

- Design FAQs: Motion Control Amplifiers

- Mathematics of Motion Control Profiles

- Get Equipment Design to Market 2X Faster

- Techniques That Improve Automated Packaging Equipment Performance