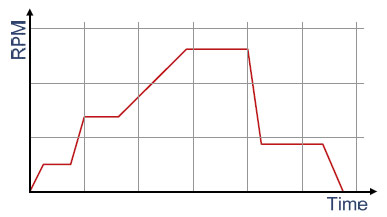

Achieve accurate velocity contouring for controlled coating thickness.

Application Challenge

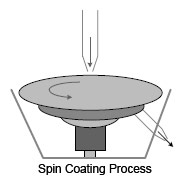

Spin coating is a procedure used to apply uniform thin films to flat substrates. In short, an excess amount of a solution is placed on the substrate, which is then rotated at high speed in order to spread the fluid by centrifugal force. The thickness of the coat is related to the spinning velocity, and for how long it is spinning at different speeds. Acceleration also affects the coated film’s properties as it provides a twisting force to the resin. Spin speeds vary between 500 rpm and 10,000 rpm, depending on the resin used and the required thickness. This use case explains how to maximize uniformity of thin film thickness.

Application Considerations

Feature / Function

Description

Velocity Range

500 rpm - 10,000 rpm

Accuracy and Repeatability

+/- 1 rpm

Acceleration/deceleration

+/-1 rpm per second

Actuator Type

Three-phase Brushless DC (BLDC) motor

Motion Control Solution

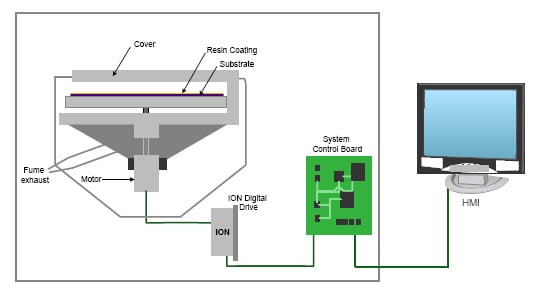

The diagram on page two shows an implementation using an ION 500 Digital Drive to control the spin velocity and acceleration. The system host computer controls the ION 500 through a serial RS485 link.

Velocity profile mode with time break points

Using the velocity profile mode the system can be set up to change the velocity at predetermined time points that match the specific thin film coating recipe. In velocity contouring profile mode the motion is controlled by changing the acceleration, velocity, and deceleration parameters while the profile is being executed.

Breakpoints

The stand alone ION digital drive supports up to 2 breakpoints. The trigger condition can be one of 10 parameters. For this application the trigger condition is time. At each trigger point the acceleration and velocity parameters are updated and the next set of parameters is buffered in preparation for the next trigger.

Field Oriented Control (FOC)

Field oriented control is ideal for this high RPM spinning application. Field Oriented Control provides the smooth motion at slow speeds as well as efficient operation at high speeds. FOC also can improve motor efficiency and can help in motor sizing. Also, the fully digital control loops, and easy to use hardware trace feature for ultra‐accurate tuning can improve the overall motion system.

The figure above illustrates the motion control connections from the system control card to the digital drive, motor and spin coating substrate. The digital drive provides motor control and amplification and can be connected via CAN or serial communication.

The motion control features and products described in this solution would also apply to many other industrial applications such as spindle control, bar code reader or drum scanners/printers.

The ION® Digital Drive is a compact, fully enclosed module that provides high performance motion control, network connectivity and power amplification for DC brush, Brushless DC or step motors. Using advanced MOSFETs and surface mount technology, ION provides very high power density in a rugged, flexible form factor. It performs profile generation, servo compensation, stall detection, field oriented control, digital torque control and many other motion control functions.

The ION® Digital Drive is a compact, fully enclosed module that provides high performance motion control, network connectivity and power amplification for DC brush, Brushless DC or step motors. Using advanced MOSFETs and surface mount technology, ION provides very high power density in a rugged, flexible form factor. It performs profile generation, servo compensation, stall detection, field oriented control, digital torque control and many other motion control functions.

PMD Products That Support Semiconductor Automation

If your existing equipment needs a performance boost or if you need to develop a new product in the shortest development time possible, learn about core advantages of using motion control products from Performance Motion Devices.

ION/CME N-Series Digital Drives

N-Series ION Digital Drives combine a single axis Magellan IC and a high performance digital amplifier into an ultra-compact PCB-mountable package. In addition to advanced servo and step motor control, N-Series IONs provide S-curve point to point profiling, field oriented control, downloadable user code, general purpose digital and analog I/O, and much more. With these all-in-one devices building a custom controller board is a snap, requiring you to create just a simple 2 or 4-layer interconnect board.

Learn more >>

Magellan Family of ICs

Magellan Single and Multi-Axis Motion Control ICs are perfect for building a motion control board from the ground up. They feature the latest in profile generation, servo loop closure, current control, and PWM (Pulse Width Modulation) generation technology and will get your project off to quick and cost effective start.

Learn more >>

Prodigy Motion Control Boards

Prodigy®/CME Machine-Controller boards provide high-performance motion control for medical, scientific, automation, industrial, and robotic applications. Available in 1, 2, 3, and 4-axis configurations, these boards support DC brush, Brushless DC, and step motors and allow user-written C-language code to be downloaded and run directly on the board. The Prodigy/CME Machine-Controller has on-board Atlas amplifiers that eliminate the need for external amplifiers. To build a fully functioning system only a single HV power supply, motors, and cabling are needed. Host interface options include Ethernet UDP and TCP, CANbus, RS-232, and RS-485.

Learn more >>

You may also be interested in:

- Optimize Control of Syringe Dispensing Application

- Field Oriented Control (FOC) - A Deep Dive

- S-Curve Motion Profiles - A Deep Dive

- Servo Tuning Deep Dive: Black art, rocket science, or walk in the park?