SUBSCRIBE TODAY!

Subscribe to our popular newsletter, Motion Control News, to get the latest announcements, technical papers, and solution notes delivered right to your inbox.

SERVICE AND SUPPORT

Whether you’re a Performance Motion Devices customer or a first-time visitor to our site, we’re here to talk with you about your engineering challenges and how we can help. We provide support for up-front motion consultation, schematic reviews, software and tuning assistance, and other problems you might run into.

If you are an equipment maker, designer, or OEM, we provide technical information and support during business hours – 9:00 am to 6:00 pm US ET. Please email support@pmdcorp.com or call us at +1-978-266-1210

If you are a Contract Manufacturer for one of our OEM customers, we provide support via email to purchaseorders@pmdcorp.com

~ OEM for the Semiconductor Industry

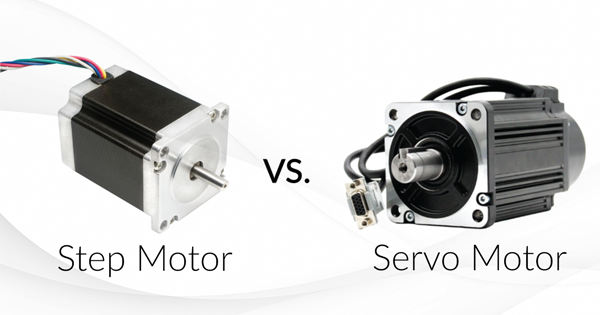

Trying to decide what electric motor(s) are best for your new machine design? Stop here. This paper outlines requirements and presents the features of various step and servo motors.

Get insight into force control in actuators, principles of motor selection, designing a low cost, high speed BLDC motor controller, our ION/CME 500, and more.

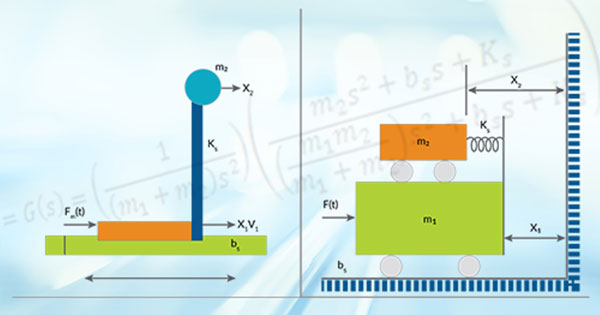

This article will explore why a machine is exhibiting mechanical resonant frequency and what tools can be used to analyze and fix it.

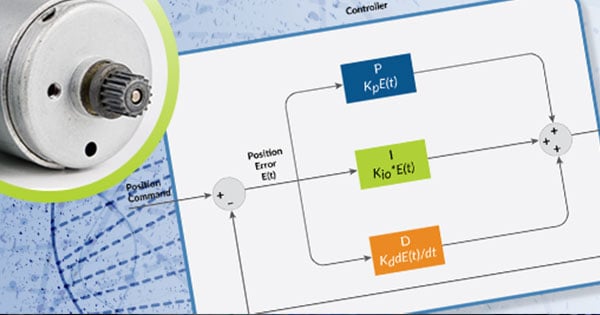

This paper provides an overview of PID (proportional, integral, derivative) based servo motor tuning, and introduces two manual tuning methods.

This webinar explores the functional requirements and critical capabilities involved in designing motion control solutions for healthcare robotic applications.

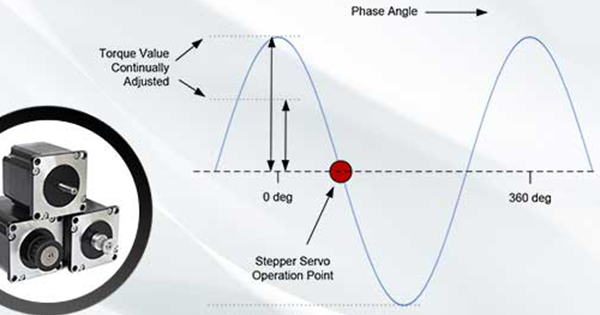

When it comes to step motors, a new drive technique called stepper servo has some engineers believing they have found the holy grail of positioning motion control - the high performance of a servo motor with the low cost of a step motor.

Subscribe to our popular newsletter, Motion Control News, to get the latest announcements, technical papers, and solution notes delivered right to your inbox.

PERFORMANCE MOTION DEVICES, INC.

80 Central Street | Boxborough, MA 01719

P: 978.266.1210 | F: 978.266.1211 | info@pmdcorp.com