Read about the most popular motion control techniques, including FOC, for multi-phase motor control, and what control techniques work best for positioning applications.

Semiconductor

The main parameter that characterizes motion in semiconductor equipment design is high precision, be it front- or back-end. Regardless of the process – lithography, metrology and inspection, wafer handling, die-attach, assembly, test – all require high accuracy and repeatability with ever-growing throughput requirements. Whether in an atmospheric or vacuum environment, Performance Motion Devices (PMD) motion control electronics (including ICs, miniature drives, digital amplifiers, and motion control boards) make these requirements possible, easier to develop, and faster to deploy.

![]()

PMD is ISO 9001:2015 and ISO 13485:2016 certified. We deliver the quality, safety and long-term availability demanded by healthcare and life sciences applications.

Read about the most popular motion control techniques, including FOC, for multi-phase motor control, and what control techniques work best for positioning applications.

During this webinar, we examine the impact of size, weight, heat, and control techniques on the path to achieving your desired performance.

A noisy or chattering servo axis is one of the most common motion problem that engineers encounter. This deep dive focuses on servo motor noise problems and how to solve them.

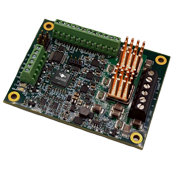

Prodigy/CME Machine-Controller boards are available in 1, 2, 3, and 4-axis configurations. They provide high performance motion control functions, on-board amplification, and Brushless DC, DC Brush, and step motor control. They allow user-written C-language code to be downloaded and run directly on the board.

PERFORMANCE MOTION DEVICES, INC.

80 Central Street | Boxborough, MA 01719

P: 978.266.1210 | F: 978.266.1211 | info@pmdcorp.com