Delta robot control means control of a three-axis ‘delta’ mechanical linkage capable of high-speed pick and place operations. Since its invention in the 1980s the delta robot has found adoption in a number of applications including food processing machinery, packaging equipment, electronics manufacturing, automated assembly equipment, dispensing machines, sorting equipment, pharmaceutical production, 3D printing and more.

In this Motion Application:

- Explore Design Considerations & Techniques

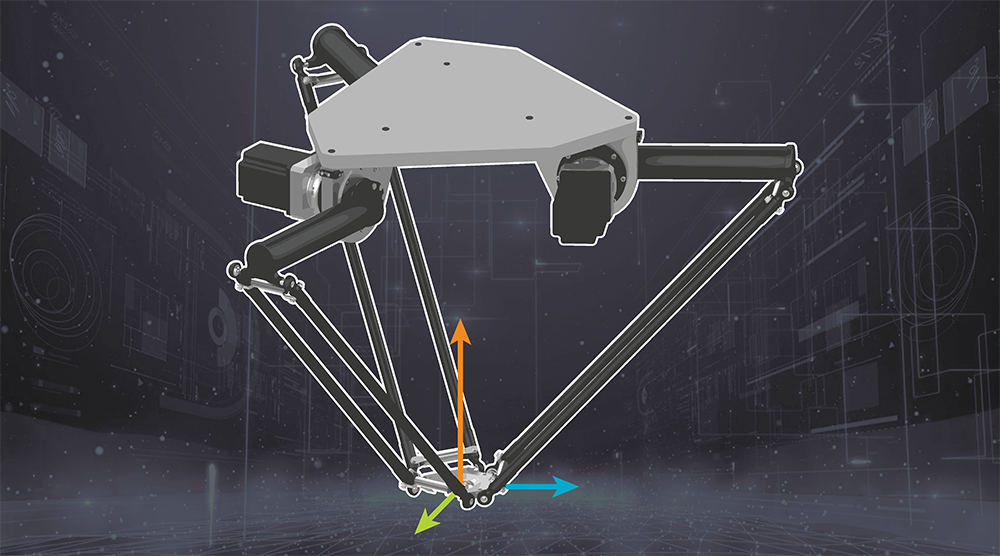

Although a relatively recent development in robot technology, delta robots have gained popularity in high speed pick and place applications due to their novel design which separates the heavier actuator mechanisms (motors and gearheads) from the actuator linkage mechanism resulting in very fast point to point moves. - Examine Application Architecture

The diagrams show a generalized drawing of delta robot mechanism and a simple example of a desired path in the XYZ (platform) space kinematically transformed to the command paths in the drive motor θ1, θ2, θ3 (base) space. - View Motion Control Solutions

Performance Motion Devices motor control drives and motion control ICs are used in a wide variety of robotic control applications including delta robots due to their unique combination of ruggedness, high performance, and affordability. PMD’s N-Series ION Digital Drives are PCB-mountable modules which can directly process kinematic conversion equations using downloaded software. PMD’s ION/CME 500 drives provide a similar capability in a cable connected module format. For embedded solutions PMD’s MC58113 positioning control ICs are ideal for sophisticated servo motor robotic control applications.

Click here to see more.