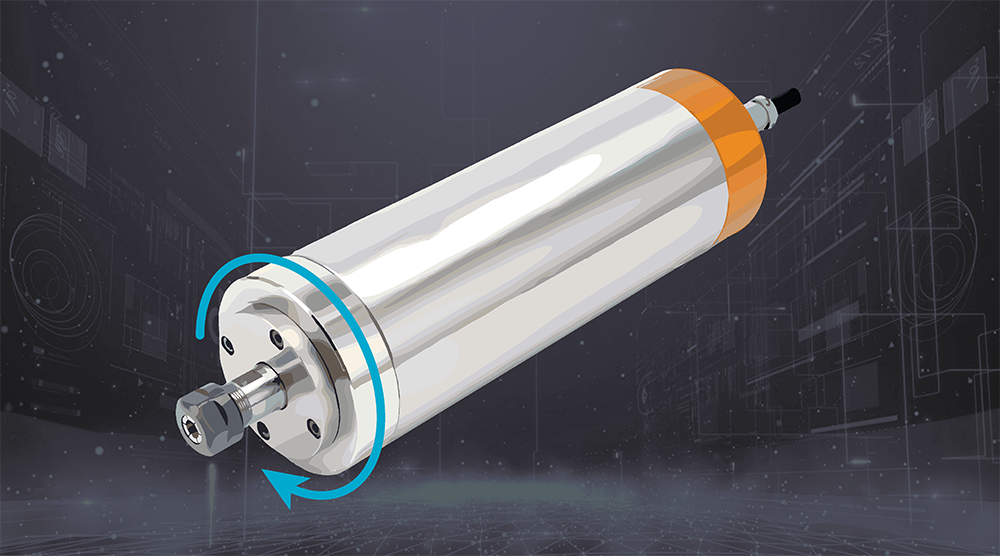

Spindle Control means controlling high speed motors (usually Brushless DC motors) in applications such as machine tool cutting, drilling, centrifuges, cryo-pumps, bar code readers, rotating marking and scanning systems, spin coating, and more. What connects all these applications is the need to drive the motor at high rotation speeds sometimes exceeding 50,000 RPM, and with high efficiency and minimal motor heating.

In this Motion Application:

- Explore Design Considerations & Techniques

The motion control challenge involved with high speed spindle control begins with the unusual nature of typical spindle motors themselves. To achieve their high rotation rate these motors typically have very low coil resistances and electrical time constants. So when driven by a PWM (Pulse Width Modulation) switching amplifier a central consideration is that the bridge circuitry operate efficiently at high PWM rates. - Examine Application Architecture

The diagram shows the calculation flow for the FOC (Field Oriented Control) technique used with Brushless DC motors, also known as Synchronous AC motors. FOC is an important technique used in spindle control to achieve the greatest efficiency and torque output at high spin rates. - View Motion Control Solutions

Since 1994 Performance Motion Devices products have been used in a range of spindle control applications including spin coating, centrifuges, bar code scanners, machine tools cutters, grinders, surgical drills, electric aircraft propulsion, centrifugal pumps, marine propulsion, and more. PMD’s Juno Velocity and Torque Control ICs are ideally suited for high performance spindle control applications, as are PMD's ION/CME N-Series Digital Drives providing up to 1 KW of output in a compact PCB-mounted module format.

Click here to see more.