Web Tension Control means control of motors and sometimes brakes for the purpose of maintaining a sheet of material (the web) at a constant tension during processing. Web tensioning is used in a large array of machines and industries including paper processing, packaging equipment, consumables fabrication, composite fabrication, textile equipment, and more.

In this Motion Application:

- Explore Design Considerations & Techniques

There are actually many ways to 'thread' a web, but the key task is to maintain the web at a controlled tension and speed, particularly in the zone where the material will be processed. In this article our focus will be on closed loop web tension control, where motors such as DC or Brushless motors are actively commanded to maintain the tension at a high level of constancy. - Examine Application Architecture

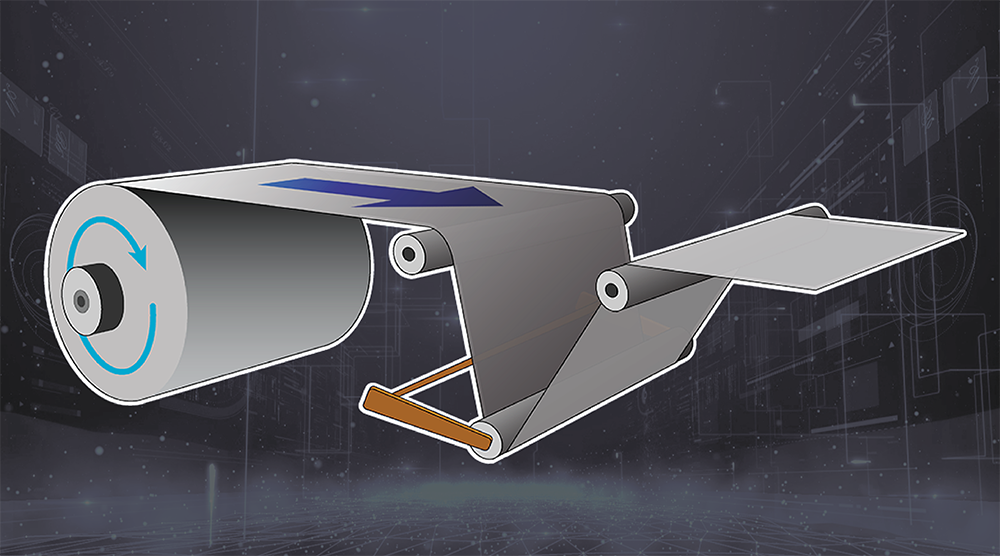

The diagram shows a generalized pathway for web tension control applications. There are many variations, and both the unwind and rewind tension zones, which in this diagram use just a torque motor or brake to maintain tension, may also utilize a closed loop tension controller in connection with a dancer or strain gauge for tension measurement. - View Motion Control Solutions

Performance Motion Devices motor control drives and intelligent amplifiers are used in a wide variety of web tensioning applications due to their unique combination of ruggedness, high performance, and affordable cost. PMD’s N-Series ION Digital Drives are PCB-mountable modules which support multiple sensor input and full customizability via downloadable user-written software. PMD’s ION/CME 500 drives provide a similar capability in a cable connected module format. For IC-based solutions PMD’s MC73112 and MC71112 motor control ICs drive BLDC and DC Brush motors respectively and are ideal for web tension control applications.

Click here to see more.