Helping robotics companies bring their projects to completion, OLogic increasingly turns to Performance Motion Devices for motion control technology without limits.

Silicon Valley–based OLogic has helped robotics and consumer electronics companies — from startups to industry leaders — bring products to market. Past customers include NVIDIA, Google, Hasbro, Panasonic, Toyota Research Institute, and Carnegie Mellon University.

OLogic brings decades of experience designing DC motor systems for a wide range of applications. But when it comes to delivering advanced motion control for robotics, even OLogic benefits from having a trusted partner.

That’s why the team repeatedly turns to Performance Motion Devices (PMD) — a company with the embedded motion control technologies, deep motion control expertise, and the engineering support to help bring complex designs across the finish line. As of mid-2025, OLogic has used PMD motion control solutions in at least four robotics projects.

For Ted Larson, CEO and co-founder of OLogic, the reason is clear: PMD consistently delivers great technology for commercial products, great solutions and tools for developers, and great support when it matters most.

Technology Built for Commercial Robotics

Larson draws a sharp line between hobbyist prototypes and commercial robots. Many developers start with off-the-shelf components, often adapted from industrial or academic settings, but soon find these parts inadequate. Meanwhile, robots also face unique challenges: space and power constraints, variable duty cycles, and the need to switch seamlessly between velocity and position control.

That’s why OLogic relies on PMD, whose ICs and drives are designed from the ground up for commercial applications. They deliver the precision, efficiency, and reliability that OLogic’s customers — from delivery robots to mobile platforms — need in the field. With PMD, OLogic can design motion systems that are robust enough for daily operation, not just one-off demonstrations.

OLogic often works with customers who have run successful trials but lack a path to volume production. The solution, Larson argues, is designing for scale from the start: “We advocate for building a highly bespoke electronic system that’s specifically designed for manufacturing,” he says.

That means consolidating electronics onto one or two boards for simpler assembly, troubleshooting, and cost reduction over time. PMD’s product range provides a clear path to this kind of bespoke design. Customers can start with development boards, migrate to motor control modules like the ION/CME N-Series intelligent mini-drives, and eventually embed PMD ICs directly into custom designs. This progression keeps costs manageable while ensuring scalability.

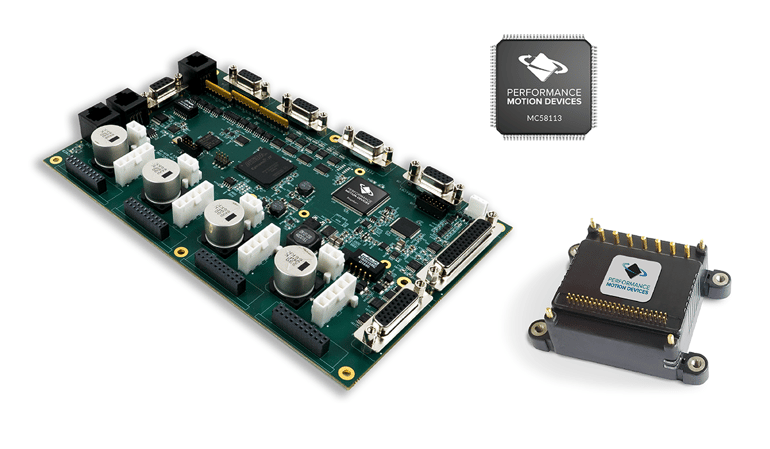

PMD’s Prodigy/CME Machine-Controller, MC58113 Positioning IC, and ION/CME N-Series Drive

OLogic has found clear advantages in using PMD’s command-based motion chips rather than starting with a raw processor. “By relying on a chip where the control algorithms and command set are already embedded, our engineers avoid the time-consuming process of writing and debugging low-level motor control code,” Larson says. “This speeds up development, reduces risk, and allows our team to focus on system-level innovation instead of reinventing the basics of motion control.”

Accelerating Development in the Field

PMD’s ecosystem of motion control solutions has repeatedly helped OLogic deliver under pressure. One notable example was OLogic’s work with Dusty Robotics on its FieldPrinter autonomous mobile robot (AMR) for construction sites. The robot’s original motion controller became unavailable during the global semiconductor shortage, jeopardizing production.

Dusty needed a replacement controller that fit within the existing footprint and integrated smoothly with the design. PMD’s ION/CME N-Series Motion Control Drive proved the perfect solution. Compact and PCB-mountable, it provided both the form factor and the advanced diagnostics Dusty’s engineers needed. By developing a custom carrier board, OLogic ensured seamless integration, allowing Dusty to continue production without missing a beat.

This episode highlighted two critical PMD strengths: reliable supply, even during a global shortage, and products versatile enough to fit demanding robotics applications. For Dusty, PMD technology helped transform a potential crisis into a smooth path forward.

PMD’s N-Series not only fit nicely within the small footprint constraints, but it also provided Dusty’s robotics engineers with essential insight and the access to internal control parameters needed to customize and troubleshoot. (To learn more about the role of the ION/CME N-Series Motion Control Drive in the FieldPrinter design, read PMD’s case study with Dusty Robotics.)

Tackling Motion Control Challenges

Designing motion control comes with its fair share of challenges. Not only is PMD there to provide the support necessary to get projects off the ground — including being very able and willing to develop custom features — PMD’s solutions give OLogic the flexibility and tools to address these issues.

- Sensorless motors: PMD chips allow engineers to add encoders and use them as sensors, creating reliable control systems without requiring dedicated motor sensors.

- Current management: Instead of oversizing motors and risking power drain, PMD ICs enable precise matching of motor, FETs, and H-bridges to ensure efficiency and stability.

- Energy handling: Large motors can generate significant energy when slowing down. PMD’s Juno chip supports intelligent shunting, pulsing resistors to dissipate excess energy safely while protecting batteries and circuitry.

Larson recalls projects requiring the control of large, heavy DC motors weighing 40–50 pounds. These motors introduced complexities such as managing excess braking energy — a challenge many off-the-shelf controllers aren’t designed to handle. With PMD solutions, OLogic engineers could integrate custom shunting circuits directly into designs, supported by the Juno chip’s intelligent energy management features.

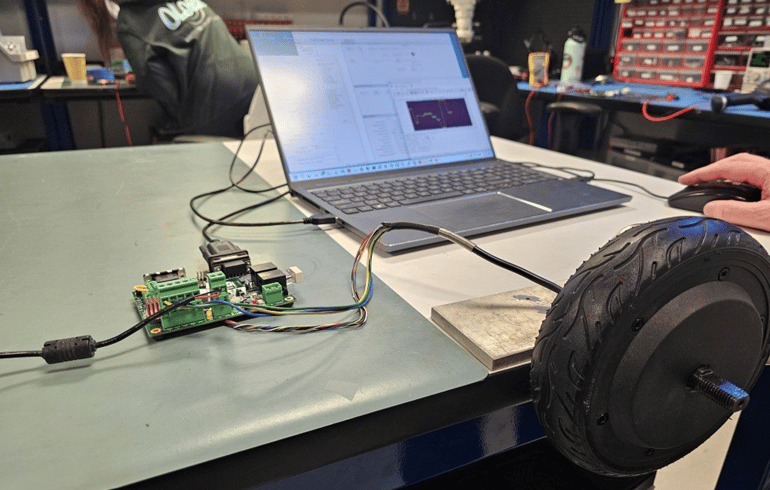

The industry has moved toward brushless DC motors, which can come with challenges that PMD motion control

solutions help to navigate.

This capability underscores one reason OLogic continues to choose PMD: the products prove themselves in demanding real-world conditions, reducing the likelihood of costly redesigns and enabling customers to scale with confidence.

Support That Makes the Difference

Technology alone doesn’t solve every challenge. For OLogic, PMD’s engineering support is equally important. Larson recalls a warehouse robot project where the customer required control of four high-powered motors at an update rate of 1,000 times per second — an ambitious benchmark on an aggressive timeline.

OLogic selected PMD’s Juno IC for its advanced velocity and torque control at a cost-effective price. But when early testing revealed that CAN bus message limitations threatened performance, OLogic turned to PMD for help. Within two days, PMD engineers delivered a firmware update that streamlined message payloads, enabling the robot to achieve its performance target.

Not only was PMD’s Juno chip easy to use and easy to control, Larson says, PMD goes the extra mile to make sure the project is a success. “If you have a problem, PMD will support you and back it up,” he says. “PMD as a company was awesome. They did exactly what they said they were going to do.”

OLogic often recommends building a motor controller from the ground up. Bespoke design requires a lot of tuning, but PMD takes the pain out of the process.

The project also demonstrated the advantage of PMD’s built-in tuning capabilities. Traditionally, fine-tuning motor control requires painstaking adjustments. PMD’s tools made the process straightforward, allowing OLogic to deliver a first revision that performed reliably under demanding conditions.

A Trusted Partner in Robotics Innovation

OLogic’s ongoing collaboration with PMD reflects a relationship that goes beyond supplier and customer. PMD provides the motion control foundation for OLogic’s designs, while also acting as an extension of its engineering team when challenges arise.

By partnering with PMD, OLogic helps its customers cross the gap from prototype to production — faster, more reliably, and with the confidence that their robots are built on commercial-grade motion control.

Motion Control Products for Robotics

Performance Motion Devices has been producing motion control ICs that provide advanced velocity, position, and torque control of DC Brush and Brushless DC motors for more than thirty years. Since that time, we have also embedded these ICs into plug and play modules and boards. While different in packaging, all PMD products are controlled by C-Motion, our easy-to-use motion control language, and are ideal for use in medical, laboratory, semiconductor, robotic, and industrial motion control applications. Notably, our solutions are also increasingly integrated into Autonomous Mobile Robots (AMRs), where precise, reliable motion control is critical to performance and efficiency.

ION/CME N-Series Drives

ION/CME N-Series Drives combine a single axis Magellan IC and a high performance digital amplifier into an ultra-compact PCB-mountable package. In addition to advanced servo and stepper motor control, N-Series IONs provide S-curve point to point profiling, field oriented control, downloadable user code, general purpose digital and analog I/O, and much more. With these all-in-one devices building a custom controller board is a snap, requiring you to create just a simple 2 or 4-layer interconnect board.

Learn more >>

MC58113 Positioning IC

The MC58113 series of ICs are part of PMD’s popular Magellan Motion Control IC Family and provide advanced position control for step, BLDC, and DC Brush motors alike. Standard features include support for CAM profiles, trapezoidal & s-curve profiling, direct encoder and pulse & direction input, and much more. MC58113 ICs have an advanced trace capability that lets you collect critical performance data as fast as twenty times per mSec, or as slow once a day.

Learn more >>

Prodigy/CME Machine Controller

Prodigy®/CME Machine Controller boards provide high-performance motion control for medical, scientific, automation, industrial, and robotic applications. Available in 1, 2, 3, and 4-axis configurations, these boards support DC Brush, Brushless DC, and stepper motors and allow user-written C-language code to be downloaded and run directly on the board. The Prodigy/CME Machine-Controller has on-board Atlas amplifiers that eliminate the need for external amplifiers.

Learn more >>

You may also be interested in:

- Robotic Wheel Drive (Motion Application)

- Mathematics of Motion Control Profiles (Article)

- Build vs Buy of a Three Axis Motion Controller (Article)

- Precision Torque Control (Motion Application)

- Introducing ION/CME N-Series Digital Drives (Webinar)

- Field Oriented Control (FOC) - A Deep Dive (Article)