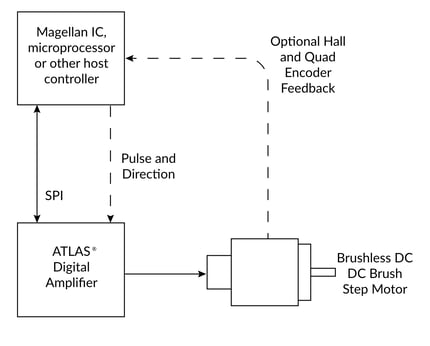

Atlas® Amplifiers are compact single-axis amplifiers that provide high-performance torque control for Brushless DC, DC Brush, and Step motors. They are packaged in a compact, solderable module and are ideal for use in positioning motion control, velocity control, and precision force control applications. Atlas amplifiers come in both a vertical and horizontal mounting configuration and are available in three power ranges: 75W, 250W, and 500W. They are ideally suited for applications such as medical equipment, laboratory automation, scientific instruments, general-purpose motion control, force feedback, and actuator control.

| Part Number | Power & Voltage | Package | Motor Type |

| Step Motor | |||

| MD241048/02VB | 75W, 12-48V | Ultra Compact, Vertical | Step Motor |

| MD241048/02HB | 75W, 12-48V | Ultra Compact, Horizontal | Step Motor |

| MD241048/05VB | 250W, 12-48V | Ultra Compact, Vertical | Step Motor |

| MD241048/05HB | 250W, 12-48V | Ultra Compact, Horizontal | Step Motor |

| MD141056/25VB | 500+W, 12-56V | Compact, Vertical | Step Motor |

| MD141056/25HB | 500+W, 12-56V | Compact, Horizontal | Step Motor |

| Brushless DC | |||

| MD231048/02VB | 75W, 12-48V | Ultra Compact, Vertical | Brushless DC |

| MD231048/02HB | 75W, 12-48V | Ultra Compact, Horizontal | Brushless DC |

| MD231048/05VB | 250W, 12-48V | Ultra Compact, Vertical | Brushless DC |

| MD231048/05HB | 250W, 12-48V | Ultra Compact, Horizontal | Brushless DC |

| MD131056/25VB | 500+W, 12-56V | Compact, Vertical | Brushless DC |

| MD131056/25HB | 500+W, 12-56V | Compact, Horizontal | Brushless DC |

| DC Brush | |||

| MD211048/02VB | 75W, 12-48V | Ultra Compact, Vertical | DC Brush |

| MD211048/02HB | 75W, 12-48V | Ultra Compact, Horizontal | DC Brush |

| MD211048/05VB | 250W, 12-48V | Ultra Compact, Vertical | DC Brush |

| MD211048/05HB | 250W, 12-48V | Ultra Compact, Horizontal | DC Brush |

| MD111056/25VB | 500+W, 12-56V | Compact, Vertical | DC Brush |

| MD111056/25HB | 500+W, 12-56V | Compact, Horizontal | DC Brush |

| Multi Motor | |||

| MD281048/02VB | 75W, 12-48V | Ultra Compact, Vertical | Multi Motor |

| MD281048/02HB | 75W, 12-48V | Ultra Compact, Horizontal | Multi Motor |

| MD281048/05VB | 250W, 12-48V | Ultra Compact, Vertical | Multi Motor |

| MD281048/05HB | 250W, 12-48V | Ultra Compact, Horizontal | Multi Motor |

| MD181056/25VB | 500+W, 12-56V | Compact, Vertical | Multi Motor |

| MD181056/25HB | 500+W, 12-56V | Compact, Horizontal | Multi Motor |

| Parameter | Value |

| Supported motor types | Brushless DC, step motor, DC Brush |

| PWM frequency | 20, 40, 80, 120 kHz |

| Current Loop rate | 20 kHz |

| Microstepping resolution | 256 microsteps per full step |

| User Programmability | Non-volatile RAM user configuration storage |

| Trace Memory | 2 KB |

| I/Os | FaultOut, Enable |

| Safety | Short Circuit, OverCurrent, I2t Current Foldback, SPI Watchdog, Overvoltage, Undervoltage |

| Operating Temperature | 0° - 40° C |

| Compliance | RoHs, CE LVD:EN60204-1, EMC-D: EN61000-6-1, EN61000-6-3, EN55011 |

| UL | Designed to UL508C, UL840, and EN60204-1 |

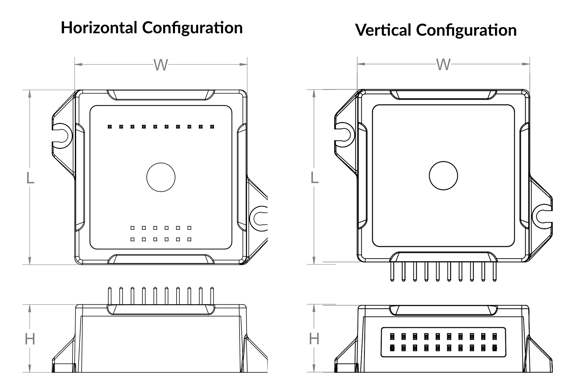

| Model | Length | Width (W) | Height |

| Ultra Compact Vertical | 1.054 in (26.8 mm) |

1.051 in (26.7 mm) |

0.526 in (13.4 mm) |

| Ultra Compact Horizontal | 1.054 in (26.8 mm) |

1.051 in (26.7 mm) |

0.526 in (13.4 mm) |

| Compact Vertical | 1.520 in (38.6 mm) |

1.517 in (38.5 mm) |

0.600 in (15.2 mm) |

| Compact Horizontal | 1.520 in (38.6 mm) |

1.517 in (38.5 mm) |

0.600 in (15.2 mm) |

| Model | Voltage Input | Peak Current | Continuous Current | Package |

| Low Power, Brushless DC | 12-48V | 3.8 Amps | 1.5 Arms | Ultra Compact |

| Low Power, step motor | 12-48V | 3.8 Amps | 1.5 Arms | Ultra Compact |

| Low Power, DC Brush | 12-48V | 3.8 Amps | 1.5 ADC | Ultra Compact |

| Medium Power, Brushless DC | 12-48V | 12.5 Amps | 5.0 Arms | Ultra Compact |

| Medium Power, step motor | 12-48V | 12.5 Amps | 4.5 Arms | Ultra Compact |

| Medium Power, DC Brush | 12-48V | 12.5 Amps | 7.0 ADC | Ultra Compact |

| High Power, Brushless DC | 12-56V | 25.0 Amps | 10.0 Arms | Compact |

| High Power, step motor | 12-56V | 25.0 Amps | 9.0 Arms | Compact |

| High Power, DC Brush | 12-56V | 25.0 Amps | 14.0 ADC | Compact |

| Specification | Standard |

| CE | LVD: EN60204-1 EMC-D: EN61000-6-1, EN61000-6-3, EN55011 |

| Electrical safety | Designed to UL508C, UL840 and EN60204-1 |

| Hazardous materials | RoHS compliant |

| Flammability | UL94-HB |

| Enclosure | IP20 |

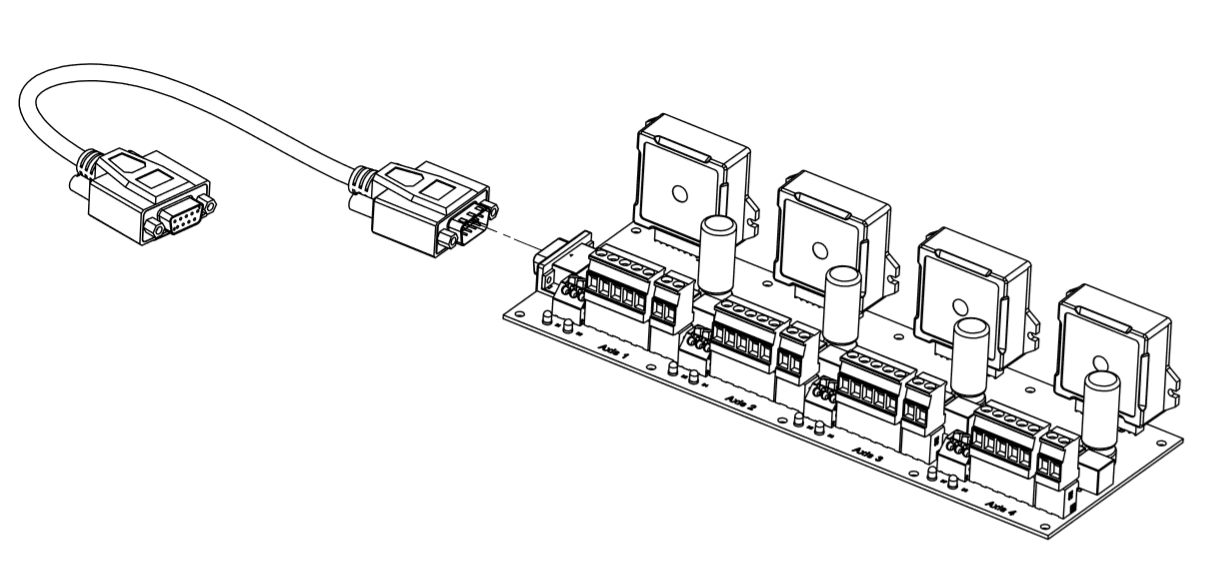

PMD Developer Kits make set-up, tuning, optimizing, and building your motion control application fast and easy.

| Developer Kit Part Number | # of Axis | Atlas Type Supported* |

| MDK1LI0000V | 1 | Vertical |

| MDK1LI0000H | 1 | Horizontal |

| MDK4LI0000V | 4 | Vertical |

| MDK4LI0000H | 4 | Horizontal |

*Atlas amplifier not included with developer kit. Atlas unit must be ordered separately.

Datasheet(s)

![]() Atlas Digital Amplifier Datasheet

Atlas Digital Amplifier Datasheet

User Guides

![]() Atlas Digital Amplifier User Manual v2.2

Atlas Digital Amplifier User Manual v2.2![]() Atlas Digital Amplifier Complete Technical Reference v2.2

Atlas Digital Amplifier Complete Technical Reference v2.2

Software Downloads

The Juno family of ICs excel at velocity and torque control and are perfect for building low cost, high performance motor or actuator controllers.

Ultra compact, rugged PCB-mountable intelligent drives that provide high-performance motion control, network connectivity, and power amplification.

The popular MC58113 provides single-axis advanced position and torque control for Brushless DC, DC Brush, and step motors. These world-class ICs are the ideal solution for your next motion control design challenge.

Compact single-axis amplifiers that provide high-performance torque control for Brushless DC, DC Brush, and step motors. Atlas amplifiers come in both a vertical and horizontal mounting configuration and are available in three power ranges.

Multi-Axis Motion Control ICs that are perfect for building your own machine control board from the ground up. They feature the latest in profile generation, servo loop closure, current control, profile synchronization, and much more.

ION Digital Drives combine a single axis Magellan IC and an ultra-efficient digital amplifier into a compact rugged package. IONs are easy-to-use plug-and-play devices that will get your application up and running in a snap.

Single and Multi-Axis Motion Boards are complete ready-to-go controllers that come in various form factors including PC-104, standalone, and standalone with built-in Atlas Amplifiers.

Pro-Motion is PMD's easy-to-use Windows-based exerciser and motion analysis program. It offers ready-to-go capabilities your entire development team will be able to share.

PERFORMANCE MOTION DEVICES, INC.

80 Central Street | Boxborough, MA 01719

P: 978.266.1210 | F: 978.266.1211 | info@pmdcorp.com