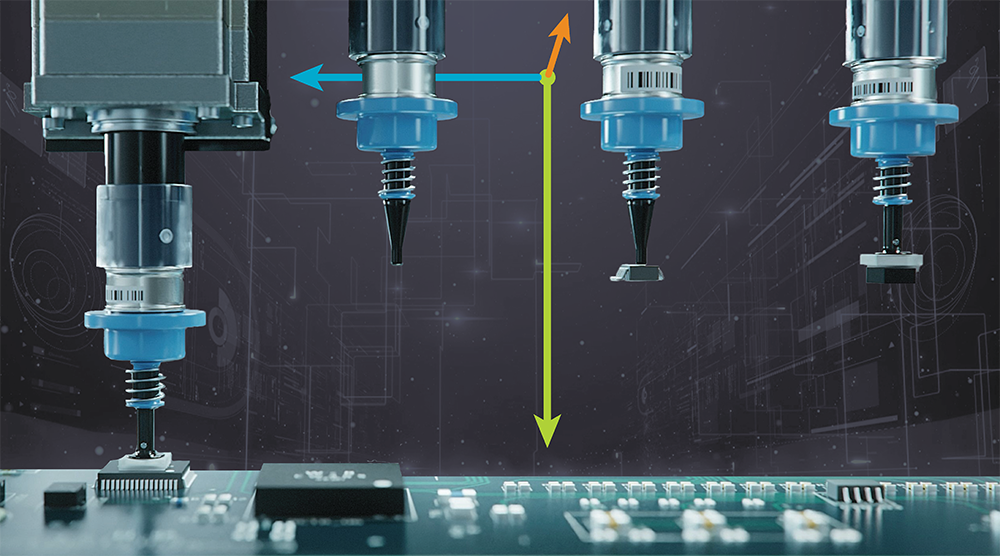

High Speed Pick and Place in this motion application will focus on the control of mechanisms used for electronics, motor, and textile production where an actuator head rapidly moves back and forth. High speed pick and place encompasses a wide range of machines including SMT (Surface Mount Technology) Pick and Place, Die Bonding Equipment, IC Insertion Machines, Motor Winding Machines, Embroidery Machines, Automated Label Applicators, and more.

In this Motion Application:

- Explore Design Considerations & Techniques

The motion control challenge involved with high speed pick and place boils down to four essential elements; minimizing vibrational energy injected into the load, choosing and optimally controlling motors capable of high acceleration rates, maximizing use of feedforward to reduce settling time, and high position and current servo loop rates. - Examine Application Architecture

The diagram shows the difference in vibrational energy injected into the driven mechanism between S-curve profiling and Trapezoidal profiling. Because s-curve profiles have smooth transitions between changes in acceleration they inject much less vibration into the mechanism. This is very important for compliant motor/actuator mechanisms such as belt drives. - View Motion Control Solutions

Since 1994 Performance Motion Devices products have been used in a range of high speed pick and place applications including electronic production equipment, embroidery machines, and label applicators. PMD’s N-Series ION drives are especially well suited for pick and place applications, as are the MC58113 family of positioning ICs.

Click here to see more.