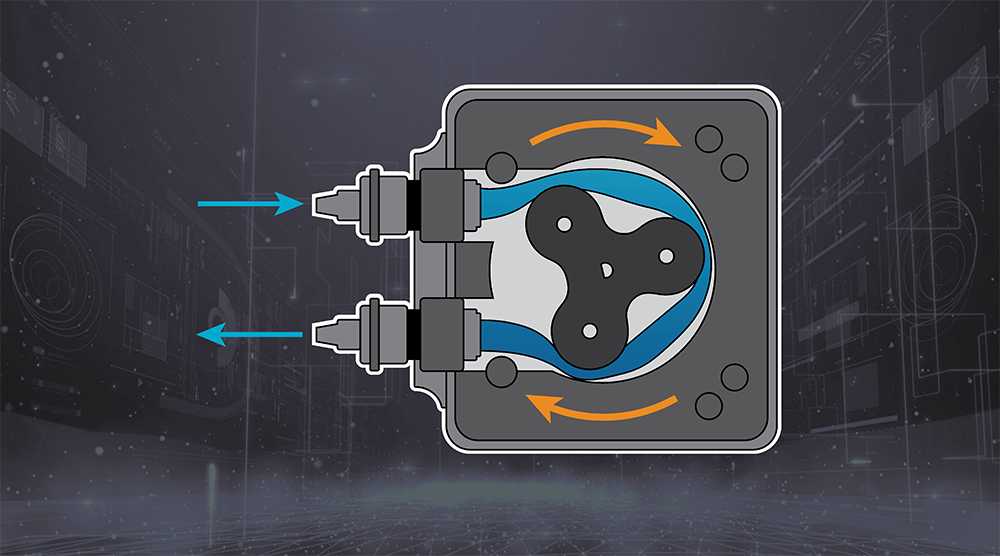

Peristaltic pump control means controlling the special mechanical characteristics of this type of pump as it rotates. Peristaltic pumps are used in a broad range of industrial and medical applications but are probably best known in patient treatment applications where bodily fluid such as blood is continuously drawn, processed, and returned to a patient. Because of the dramatic changes in reflected load as the pump rotates, peristaltic pump control presents unique challenges to minimize pressure fluctuations and pulsing in the amount of delivered fluid.

In this Motion Application:

- Explore Design Considerations & Techniques

The motion control challenge involved with peristaltic pumps derives from two specific characteristics of how the pump functions. The first is that these pumps typically rotate slowly, 60 RPM all the way down to a complete standstill depending on the application. The second is that the load experienced by the motor varies dramatically as the squeezed tube engages, or disengages from the roller. - Examine Application Architecture

The diagram shows the control flow for a position PID (proportional, integral, derivative) control loop including table-driven torque feedforward and position compensation. - View Motion Control Solutions

Since 1992 Performance Motion Devices products have been used in a range of peristaltic pump control applications, particularly for dialysis and plasma collection machines. PMD’s MC53113 Motion Control IC is ideally suited for high performance pump control applications, as are PMD's ION/CME N-Series Digital Drives which provide precise control in a compact PCB-mounted module format.

Click here to see more.