Pumps that move liquid precisely are at the heart of many medical and lab automation applications. Get an understanding of what types of fluid pumps will work best in your motion control application.

Lab Automation

Lab automation refers to a broad array of devices that employ robotics, software, and mechanical systems to accelerate laboratory processes, reduce errors, and free up laboratory staff to do other important tasks. Motion control technology is at the heart of several lab automation design functions that require uncompromising high precision, such as pipetting, liquid handling, mixing, and stirring. Over half of the world's largest lab automation manufacturers use PMD motion control solutions - ICs, modules, and boards – to meet their requirements for high precision, safety, and long-term supply stability.

![]()

PMD is ISO 9001:2015 and ISO 13485:2016 certified. We deliver the quality, safety and long-term availability demanded by healthcare and life sciences applications.

Pumps that move liquid precisely are at the heart of many medical and lab automation applications. Get an understanding of what types of fluid pumps will work best in your motion control application.

This webinar will explore the challenges that medtech innovators face in achieving ultra-precise motion control and today's potential solutions.

In this article we will look at four important trends in motion control technology for applications involving medical and laboratory equipment.

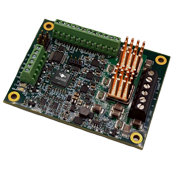

Prodigy/CME Machine-Controller boards are available in 1, 2, 3, and 4-axis configurations. They provide high performance motion control functions, on-board amplification, and Brushless DC, DC Brush, and step motor control. They allow user-written C-language code to be downloaded and run directly on the board.

PERFORMANCE MOTION DEVICES, INC.

80 Central Street | Boxborough, MA 01719

P: 978.266.1210 | F: 978.266.1211 | info@pmdcorp.com