This paper discusses an advanced control technique called closed loop stepper. This motion control technique is finding wide adoption in a range of cost-sensitive industrial applications.

Industrial

Motion control technology is the backbone of modern industrial equipment design, enhancing productivity, reducing human error, and opening the door to advanced automation and innovation. In industrial settings, precise motion control systems ensure consistent and accurate automation of production processes, accelerating throughput while reducing defects and waste. Precision motion control is vital for the packaging, food and beverage, plastics, machine tools, metal cutting, textile industries, and others. In fact, motion control is at the core of industrial robotics, where precise motion is essential for various positioning, cutting, and movement activities. PMD’s wide range of products, including ICs, modules, and boards, excel at high-precision position, velocity, and torque control. Our motion control portfolio is uniquely designed to help you create the high-performance, reliable, and scalable industrial machines that drive your business forward.

![]()

PMD is ISO 9001:2015 and ISO 13485:2016 certified. We deliver the quality, safety and long-term availability demanded by healthcare and life sciences applications.

This paper discusses an advanced control technique called closed loop stepper. This motion control technique is finding wide adoption in a range of cost-sensitive industrial applications.

Read about the 3 core motion control techniques that can improve performance: Web Tension Control, Proportional Material Spacing, and CAM-based profiling.

This paper looks at building vs buying a three axis PCB-based positioning motion controller. It examines the motion control design effort and cost.

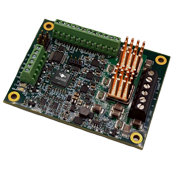

Prodigy/CME Machine-Controller boards are available in 1, 2, 3, and 4-axis configurations. They provide high performance motion control functions, on-board amplification, and Brushless DC, DC Brush, and step motor control. They allow user-written C-language code to be downloaded and run directly on the board.

PERFORMANCE MOTION DEVICES, INC.

80 Central Street | Boxborough, MA 01719

P: 978.266.1210 | F: 978.266.1211 | info@pmdcorp.com