This guide compiles PMD positioning motion control IC application examples for BLDC, DC Brush, and step motors. High level control flow diagrams allow users to quickly choose and adapt an approach. Each description provides feedback and communication options along with other useful application information.

PMD Positioning ICs Summary

The Magellan® family of ICs represent PMD’s state of the art positioning motion control ICs. These ICs are provided in both a single axis configuration (MC58113 family ICs) and multi-axis configuration (MC58000 family ICs).

Depending on the type of motor to be controlled, they provide servo loop closure, on-board commutation for brushless and closed loop stepper motors, and high-speed pulse and direction outputs. They also provide current control, short circuit protection, and many other amplifier-related control and safety functions. Together, these products provide a software compatible family of dedicated motion control ICs that can handle a large variety of motion control applications.

Feature List

- Positioning Motion Control ICs for Brushless DC, DC Brush and step motors in a 1 to 4-axis package

- S-curve, trapezoidal, velocity contouring, and electronic gearing profiles

- Serial RS232/485, Parallel, CANbus, and SPI (Serial Peripheral Interface) communications

- Advanced PID filter with velocity and acceleration feedforward

- Field Oriented Control of BLDC motors

- PWM bridge control signal output with programmable deadtime and charge pump refresh

- Programmable dual biquad filters

- Velocity, position, and acceleration changes on-the-fly

- Incremental encoder quadrature input (up to 25 Mcounts/sec)

- Programmable loop time to 50 µsec

- Four channel dedicated motion trace function for performance optimization

- Two directional limit switches, index input, and home indicator per axis

- Axis settled indicator, tracking window and automatic motion error detection

- Dual loop servo control

- Packaged in 144-pin and 100-pin TQFP formats

- Synch pin allows multiple axes synchronization within <1 µsec

- High performance current control of each motor phase

- I2t foldback, overcurrent, over/undervoltage and overtemperature detect

MC58113 Typical Applications

Position & Current Control of Brushless DC and DC Brush Motors

In this application a MC58113, MC53113, or MC51113 IC receives commands from a host microprocessor, PC, or other controller. The host provided commands, sent via CAN, serial, or SPI, specify parameters such as the desired trajectory profile, servo PID settings, current gain settings, and other parameters. PWM amplifier control signals are output to a three-phase or single H-bridge located on the same board and current feedback signals from this switching bridge are input directly into the MC58113 series IC. The above diagram shows a Brushless DC motor but similar position control can be provided for DC Brush motors.

Quadrature encoder and Hall-sensor signals can be input for Brushless DC motors however only one of these two is required. For DC Brush motors encoder feedback is required for positioning control.

Position & Current Control of Microstepping Step Motors

In this application a MC58113 or MC54113 IC receives commands from a host microprocessor, PC, or other controller. The host provided commands, sent via CAN, serial, or SPI, specify parameters such as the desired trajectory profile, microstepping resolution, current gain settings, and other parameters. PWM amplifier control signals are output to a dual H-bridge amplifier located on the same board and current feedback signals from the switching circuit are input directly back to the MC58113 series IC.

Quadrature encoder signal input is supported but is optional for step motor control.

Position & Current Control of Brushless DC, DC Brush or Step Motors using Atlas Amplifier

In this application a MC58113, MC51113, MC53113, or MC54113 IC receives commands from a host microprocessor, PC, or other controller. The host provided commands, sent via CAN, serial, or SPI, specify parameters such as the desired trajectory profile, servo PID settings, current gain settings, and other parameters. The MC58113 series IC commands an Atlas Amplifier located on the same board which provides current control and amplification. The above diagram shows a Brushless DC motor but similar control can be provided for DC Brush and step motors.

Quadrature encoder and Hall-sensor signals can be input for Brushless DC motors however only one of these two is required for position control. For DC Brush motors encoder feedback is required for position control. For step motors quadrature encoder input is supported but is optional.

Closed Loop Stepper Operation of Step Motors

In this application a MC58113 or MC54113 IC executes closed loop stepper control of a step motor. In this control mode the step motor is operated as a two-phase servo motor, using commutation and a variable current command rather than traditional microstepping control. Relative to normal step motor operation closed loop control provides less heat generation in the motor, higher acceleration, and eliminates lost steps.

Quadrature encoder input is required for closed loop step motor operation. Other than the approach toward position and current control, the control features provided with this configuration are the same as for the previous application examples.

CAM Profile Control of Brushless DC, DC Brush, or Step Motors

In this application a MC58113, MC53113, MC51113, or MC54113 IC inputs a quadrature position data stream from an external encoder and uses it as the master input for execution of a cam or electronic gear profile. Prior to profile operation the cam profile shape is loaded by the user into the MC58113’s RAM memory. Execution of camming functions and of other complex shapes is enabled via User Defined Profile Mode, which is a trajectory generator available in a special version of the MC58113. For more information on User Defined Profile Mode contact your local PMD representative.

The above diagram shows a Brushless DC motor but similar control can be provided for DC Brush and step motors.

Synchronized Multi-Axis Control of Brushless DC, DC Brush, or Step Motors

In this application MC58113, MC53113, MC51113 or MC54113 ICs are connected in a multi-axis configuration. A single host such as a microprocessor, PC, or other controller sends commands to the connected MC58113 series ICs via CAN, multi-drop serial, or SPI. For applications which require tight synchronization MC58113 series ICs support a hardware Synch signal which allows sub-microsecond synchronization of all connected axes.

Depending on the application, standard Magellan profile modes such as trapezoidal, S-curve, or velocity contouring profiles may be used. Alternatively, multi-dimensional synchronized contouring is available via User Defined Profile Mode, which is a trajectory generator available in a special version of the MC58113. For more information on User Defined Profile Mode contact your local PMD representative.

MC5800 Typical Applications

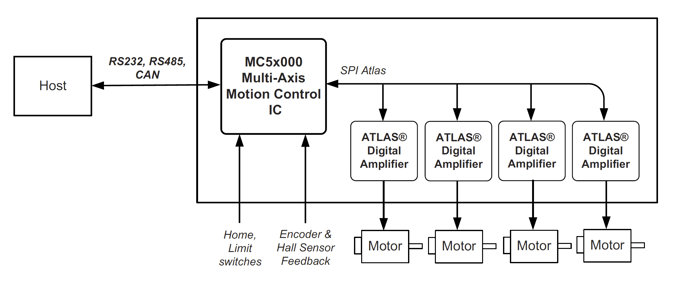

Multi-axis Motion Control Board for DC Brush, Brushless DC, or Step Motors Using On-Board Atlas® Amplifier Modules

In this application the Magellan MC5x000 Motion Control IC forms the heart of a dedicated multi-axis motion controller board. The Magellan IC-based controller is commanded directly by a host via an RS232, RS485, or CANbus network connections and provides high performance profile generation and position control of DC Brush, Brushless DC, and step motors. Quadrature encoders provide motor position feedback, and if Brushless DC motors are used Hall sensors provide commutation feedback. With step motors encoder feedback is optional. Additional supported signals include a home switch, directional limit switches, general purpose AxisIn and AxisOut signals, and more.

Atlas Amplifiers are single axis devices which provide high performance current control and amplification. They receive a continuous stream of torque or pulse & direction commands from the Magellan IC. Atlas amplifiers come in three power levels, 75W, 250W, and 500W and support DC Brush, Brushless DC, and step motors. To power the board an external power supply provides the motor voltage (HV) which powers a DC-to-DC converter used to generate 3.3V DC for board logic. The Atlas amplifiers also input this same HV voltage to power their internal logic as well as a 5V output which can be used to power motor encoders and hall sensors.

In this diagram four axes are shown but 1, 2, and 3-axis versions of the Magellan IC are available as well.

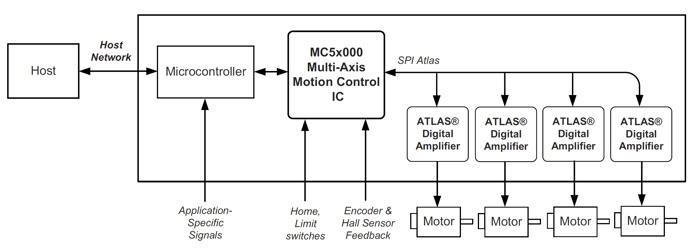

Multi-axis Motion Control Board for DC Brush, Brushless DC, or Step Motors Using On-Board Microcontroller for User Application Execution

In this application the Magellan MC5x000 Motion Control IC provides motion control functions such as profile generation and servo loop but is commanded locally, by an on-board microcontroller. This microcontroller may operate the machine standalone, or may process commands from a host interface and pass various motion commands to the Magellan Motion Control IC. Quadrature encoders provide motor position feedback, and if Brushless DC motors are used Hall sensors provide commutation feedback. With step motors encoder feedback is optional. Additional supported signals include a home switch, directional limit switches, general purpose AxisIn and AxisOut signals, and more.

Atlas Amplifiers are single axis devices which provide high performance current control and amplification. They receive a continuous stream of torque or pulse & direction commands from the Magellan IC. Atlas amplifiers come in three power levels, 75W, 250W, and 500W and support DC Brush, Brushless DC, and step motors.

To power the board an external power supply provides the motor voltage (HV) which powers a DC-to-DC converter used to generate 3.3V DC for board logic. The Atlas amplifiers also input this same HV voltage to power their internal logic as well as a 5V output which can be used to power motor encoders and hall sensors.

In this diagram four axes are shown but 1, 2, and 3-axis versions of the Magellan IC are available as well.

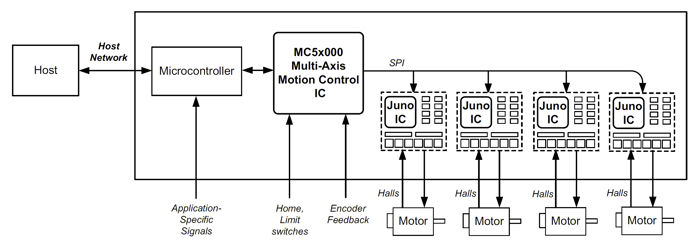

Multi-axis Motion Control Board for DC Brush, Brushless DC, or Step Motors Using On-Board Juno® Torque Control ICs

In this application the Magellan MC5x000 Motion Control IC provides high performance profile generation and position control of DC Brush, Brushless DC, and step motors. Quadrature encoders provide motor position feedback, and if Brushless DC motors are used Hall sensors provide commutation feedback. With step motors encoder feedback is optional. Additional supported signals include a home switch, directional limit switches, general purpose AxisIn and AxisOut signals, and more.

This application is similar to the previous application except that in this design rather than Atlas Amplifiers, Juno Torque Control ICs are used. These ICs receive a continuous stream of current or pulse & direction commands from the Magellan IC and generate PWM bridge control signals to drive on-board switching amplifier circuitry. In addition, Juno ICs directly input analog signals which are used to provide high performance current control and amplifier safety monitoring.

To power the board an external power supply provides the motor voltage (HV) which also powers a DC-to-DC converter used to generate 3.3V DC for card logic, 5V for encoder and hall sensor power, and 15V for amplifier pre-driver circuitry.

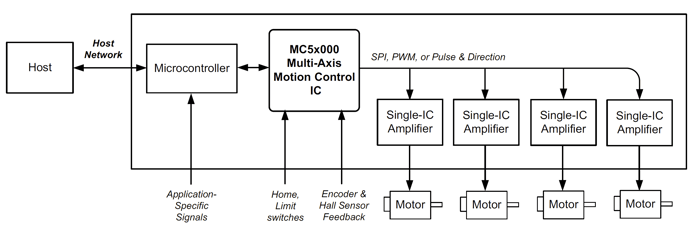

Multi-axis Motion Control Board for DC Brush, Brushless DC, or Step Motors Using Single-IC On-Board Amplifiers

In this application the Magellan MC5x000 Motion Control IC provides high performance profile generation and position control of DC Brush, Brushless DC, and step motors. Quadrature encoders provide motor position feedback, and if Brushless DC motors are used Hall sensors provide commutation feedback. With step motors encoder feedback is optional. Additional supported signals include a home switch, directional limit switches, general purpose AxisIn and AxisOut signals, and more.

This application is similar to the previous application except that in this design single-IC amplifiers are used. Available for step motors, DC Brush, and Brushless DC motors these ICs typically can provide up to 4 amps of current. Relative to an Atlas Amplifier or Juno IC based amplifier the performance is not as high and in general these ICs do not provide current control. Nevertheless these ICs may still be adequate for many applications.

To power the board an external power supply provides the motor voltage (HV) which also powers a DC-to-DC converter used to generate 3.3V DC for board logic, and 5V for encoders (if used). Most single-IC amplifiers accept a single HV power input.

Multi-axis Motion Control Board for DC Brush, Brushless DC, or Step Motors Using Off-Board Amplifiers

In this application the Magellan MC5x000 Motion Control IC provides high performance profile generation and position control of DC Brush, Brushless DC, and step motors. Quadrature encoders provide motor position feedback, and if Brushless DC motors are used Hall sensors provide commutation feedback. With step motors encoder feedback is optional.

This application is similar to the previous applications except that in this design there are no on-board amplifiers and instead +/- 10V analog output signals or pulse & direction signals are used to command off-board amplifiers. The +/- 10V amplifier command signals are generated from 16-bit data words output by the Magellan IC using on-board D/As. To control step motors pulse & direction signals are used rather than +/-10V signals, and these digital signals connect to off-board step motor amplifiers.

To power the board an external power supply provides the motor voltage (HV) which powers a DC-to-DC converter used to generate 3.3V DC for board logic, 5V for encoders (if used), and +/- 12V for generation of the +/- 10V output signals. Alternatively one or more of these voltage supplies may be provided via individual power inputs.

PMD Products Utilized in this Guide

The Magellan Family of Motion Control ICs supports a wide range of motors and system designs, as illustrated in the application examples provided. When optionally combined with Atlas Digital Amplifiers or Juno Torque Control ICs, Magellan ICs manage high-level motion tasks such as trajectory generation, profile control, and feedback processing, while Atlas and Juno components provide precise current control and drive output. This division of roles enables scalable, high-performance control of DC Brush, Brushless DC, and step motors.

MC58113 Series ICs

The MC58113 series of ICs are part of PMD's popular Magellan Motion Control IC Family and provide advanced position control for stepper, Brushless DC, and DC Brush motors alike. Standard features include FOC (Field Oriented Control), trapezoidal & s-curve profiling, direct encoder and pulse & direction input, and much more. The MC58113 family of ICs are an ideal solution for your next machine design project.

Learn more >>

Magellan Multi-Axis ICs

Magellan Multi-Axis Motion Control ICs feature the latest in profile generation, servo loop closure, and PWM (Pulse Width Modulation) technology and will get your project off to quick and cost-effective start. Available in 1, 2, 3, and 4-axis versions, these flexible, programmable devices control Brushless DC, DC Brush, and step motors and come in compact TQFP (Thin Quad Flat Pack) packages.

Learn more >>

Juno Family of ICs

The Juno family of ICs are perfect for building your own low cost, high performance controller. Junos excel at velocity and torque control, with features such as FOC (Field Oriented Control), profile generation, high/low switching amplifier control signal generation, leg current sensing, and more. Available in packages as small as 7mm x 7mm and costing $12 in quantity, these ICs are an ideal solution for your next controller design.

Learn more >>

Atlas Digital Amplifier

Atlas Digital Amplifiers are compact, single-axis modules designed for high-performance torque control of step, DC Brush, and Brushless DC motors. Available in vertical or horizontal mount configurations and in three discrete power levels (75 W, 250 W, and 500 W), these amplifiers support ultra-efficient digital current control, field-oriented commutation, user-programmable gain, and integrated protection features. When paired with Magellan ICs, Atlas amplifiers provide a compact and high-performance motor control solution that works seamlessly with trajectory generation, encoder feedback, and motion profiling.

Learn more >>

You may also be interested in:

- How To Control Stepper Motors (Article)

- CAM Profiling (Motion Application)

- Mathematics of Motion Control Profiles (Article)

- Feedforward in Motion Control - Vital for Improving Positioning Accuracy (Article)