Pan & tilt pointing means motion control of a mechanical system that can ‘pan’ (rotate around a vertical axis) and tilt (rotate around a horizontal axis). There are a large variety of machines that use a pan & tilt pointing mechanism including security cameras, laser pointing systems, fire control systems, film production equipment, radar control systems, and more.

Pan and tilt mechanisms share one main thing in common: the nature of the motion itself with one axis rotating around a vertical axis and the other rotating around a horizontal axis. After that the similarities end with the motor types and control systems employed varying significantly depending on the end application.

Cost sensitive applications, especially security cameras, typically use two-phase step motors. Microstepping control of the step motor is most common because compared to full or half step schemes microstepping generates less noise, and because the step motor’s positioning resolution is greatly expanded. For cameras which record a video image while panning (or tilting) high microstep resolution is critical for a good result.

Although still rare, closed loop stepper control which drives the step motor as a servo motor is finding adoption in specialized camera pointing applications where the very smoothest motion is required and where the axes need to accelerate/decelerate very fast.

For larger pan & tilt systems such as those used with film and television cameras, radar pointing systems, and fire control mechanisms three-phase Brushless DC motors are the norm. These motors are driven using position servo control loops which allow sophisticated feedforward compensation techniques to be applied. This technique is especially important for systems which slew very rapidly such as fire control systems and high speed camera applications used in sports and nature filming.

For such ultra-high performance servo-based systems a full understanding of the resonance characteristics of the load is vital. The best control solutions not only use resonance dampening filters in the control loop such as provided by biquad filters, they also seek to avoid stimulating resonance in the load by using smooth s-curve profiles or special trajectory profiles tuned to avoid injecting resonance into the load.

Finally, depending on the end application, the motion system may need to provide coordinate transformation. For example if a laser mounted on a pan & tilt mechanism is used to ‘paint’ on a flat surface a transformation of the target reference frame (the flat surface) to the pin & tilt frame must occur. This type of coordinate re-mapping falls under the general heading of kinematic transformation and is common in other motion applications such as SCARA arm control where the actuator mechanical arrangement is not orthogonal.

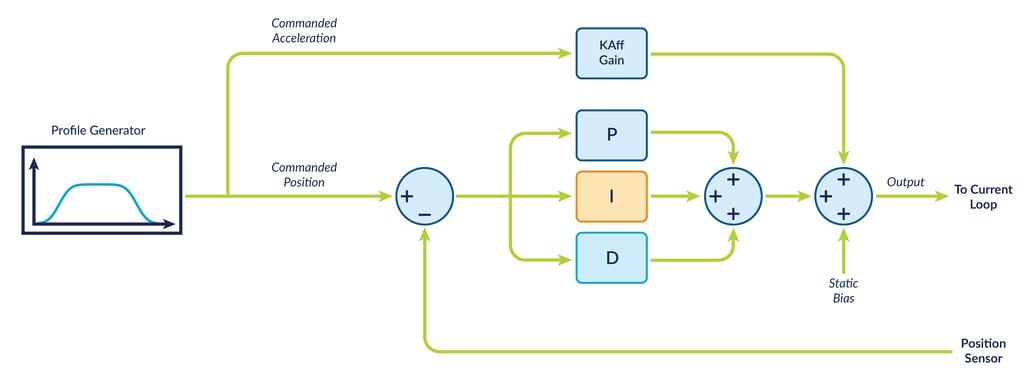

The diagram below shows the control flow for one axis of a servo-based pan & tilt motion controller. Because the pan and the tilt motion axes do not directly interact the controller consists of two such control setups, one for the pan axis, one for tilt.

Since 1994 Performance Motion Devices products have been used in a wide range of pan & tilt pointing applications including security cameras, laser pointing systems, antenna pointing, and more. PMD’s MC58113 and MC58000 Magellan Motion Control ICs are ideally suited for use in pan & tilt position controllers as are PMD’s N-Series ION Drives.

PERFORMANCE MOTION DEVICES, INC.

80 Central Street | Boxborough, MA 01719

P: 978.266.1210 | F: 978.266.1211 | info@pmdcorp.com