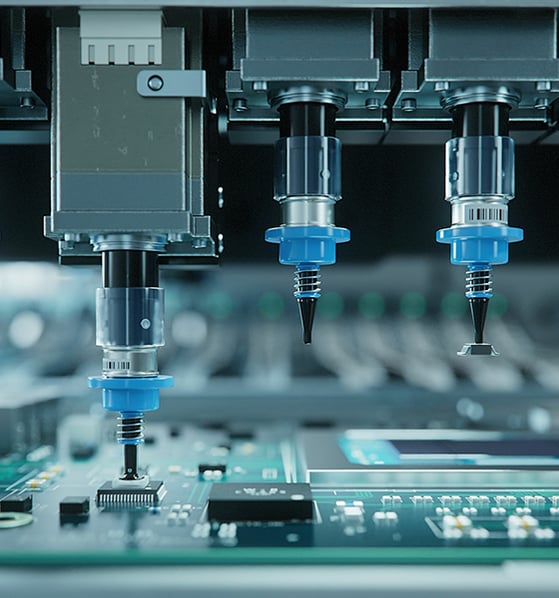

High Speed Pick and Place in this motion application will focus on the control of mechanisms used for electronics, motor, and textile production where an actuator head rapidly moves back and forth. High speed pick and place encompasses a wide range of machines including SMT (Surface Mount Technology) Pick and Place, Die Bonding Equipment, IC Insertion Machines, Motor Winding Machines, Embroidery Machines, Automated Label Applicators, and more.

The motion control challenge involved with high speed pick and place boils down to four essential elements; minimizing vibrational energy injected into the load, choosing and optimally controlling motors capable of high acceleration rates, maximizing use of feedforward to reduce settling time, and high position and current servo loop rates.

The most impactful way to minimize injected vibrational energy is through the use of s-curve profiling. A typical pick and place mechanism makes a point-to-point move from and to a commanded position. A key consideration is injecting as little vibrational energy as possible into the mechanism during the move. Seven-segment s-curve profiles, which do not have acceleration discontinuities (unlike a trapezoidal profile, which instantaneously changes acceleration) achieve this and thereby result in reduced settling time.

Another important motion technique used with high speed pick and place is selecting motors and mechanisms capable of high rates of acceleration. For rotary motors this means selecting motors with high torque output relative to their rotational inertia. Typically Brushless DC motors serve this purpose but new motor/control combinations such as step motors driven using a closed loop stepper technique can equal or even exceed some BLDC motor acceleration specs.

For low to medium accuracy applications linear belt drive mechanisms are favored because they add very little mass to the moving part of the arm. Alternatively for higher resolution applications linear Brushless DC direct drive motors are used. Although more expensive, they provide accuracy limited only by the encoder that is used and very high acceleration rates.

Another important motion technique for maximizing throughput in pick and place mechanisms is acceleration feedforward. Acceleration feedforward is a position servo loop technique that minimizes the work that the position servo loop needs to do, thereby helping to provide high tracking accuracy particularly during acceleration and deceleration trajectory phases. In short, acceleration feedforward helps the actuator 'stick the landing' by minimizing settling time.

Finally, it goes without saying that mechanisms which need to move rapidly from point A to point B need to have high servo and current loop rates. Die bonding and embroidery machines are particularly noteworthy in this regard, regularly achieving 1,000 transfers per minute or higher. Modern high speed motion controllers are up to the challenge, now regularly providing servo sample times of 100 uSecs or less (10 kHz), and current loop rates of 50 uSecs or less (20 kHz).

The diagram below shows the difference in vibrational energy injected into the driven mechanism between S-curve profiling and Trapezoidal profiling. Because s-curve profiles have smooth transitions between changes in acceleration they inject much less vibration into the mechanism. This is very important for compliant motor/actuator mechanisms such as belt drives.

Since 1994 Performance Motion Devices products have been used in a range of high speed pick and place applications including electronic production equipment, embroidery machines, and label applicators. PMD’s N-Series ION drives are especially well suited for pick and place applications, as are the MC58113 family of positioning ICs.

PERFORMANCE MOTION DEVICES, INC.

80 Central Street | Boxborough, MA 01719

P: 978.266.1210 | F: 978.266.1211 | info@pmdcorp.com